Solfre Polyurethane Adhesives - Streamlining Production for a UK Composite Panel Manufacturer

For 40 years, Chemique Adhesives has been committed to building strong relationships with customers and boosting manufacturer productivity through superior bonding solutions

This case study explores our partnership of more than fifteen years with Gilcrest Manufacturing, a leading composite panel manufacturer, demonstrating how their transition to Chemique’s Solfre polyurethane adhesive resulted in a more efficient production process and reduced operational costs.

From Challenge To Opportunity: Advanced Adhesive Solutions & Measurable Results

Based in Bristol in the UK and founded in 2002, Gilcrest Manufacturing specialises in high-quality, custom-engineered composite panels tailored to a wide range of industries. Their expert team delivers advanced solutions with a key focus on cleanrooms and other controlled environments, providing a variety of panel options with unmatched reliability, durability, and performance, trusted by many global industry leaders.

Gilcrest’s panels are renowned for meeting stringent performance requirements. Therefore, selecting the optimal adhesive was essential to achieving superior panel lamination quality and maintaining the rigorous standards associated with their product range. The company faced a challenge: finding a reliable panel bonding solution capable of delivering a strong, long-lasting performance even when exposed to harsh chemicals and fluctuating temperatures. This solution also had to support efficient, high-volume panel production, comply with industry-specific standards, and offer cost savings without compromising on quality. Furthermore, Gilcrest also sought a partnership focused on product advancement, ongoing improvement, and technical support.

Transition to Polyurethane Adhesives: Benefits & Implementation

Chemique Adhesives provided a custom bonding solution from their Solfre 2 range of two-component polyurethane adhesives, known for their exceptional strength and excellent resistance in demanding applications. Polyurethane adhesives are widely regarded as the premium choice for panel lamination, delivering high-strength, reliable bonds that endure diverse environmental conditions. Solfre 3290, a two-part PU adhesive, was selected for its flexibility, controlled cure time, and high-performance bonding in the most demanding conditions, making it ideal for cleanroom-grade panels.

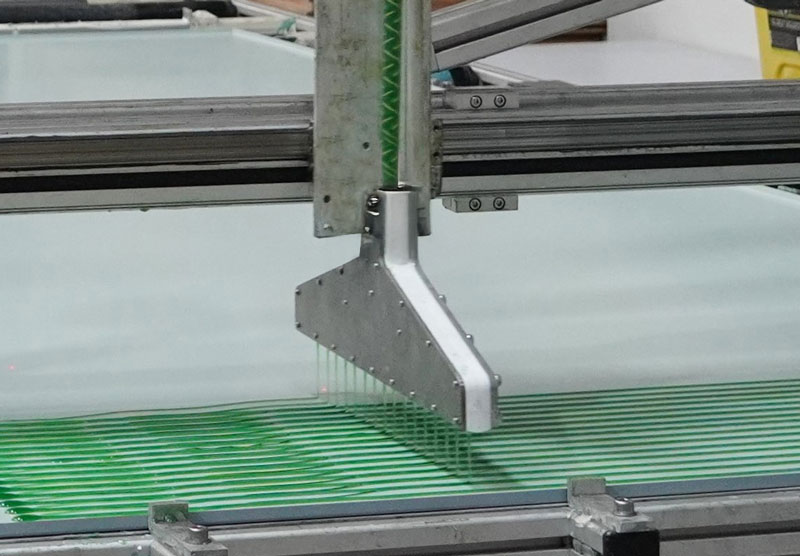

The advanced formula is developed using a controlled and accurate mix of polyol and isocyanate to form an exceptionally strong bond, crucial to panel manufacturing. To optimise application and production efficiency, Chemique installed two new bead dispensing systems, tailored to Gilcrest’s production facility. This not only reduced adhesive waste but also improved application precision and boosted throughput, contributing to faster manufacturing cycles and greater production output.

Phil Carter, Business Development Manager at Chemique Adhesives commented, “During the initial testing, it was clear that this two-part polyurethane adhesive was the ideal solution for Gilcrest’s requirements, highlighting its excellent bond to the laminated material. We were able to fine-tune the open and cure times to perfectly match the application requirements, resulting in a successful final product."

Compliance & Accreditation Support

Chemique’s relationship with Gilcrest has steadily grown over the past fifteen years. Their dedicated in-house adhesive testing laboratories and team of chemists play a crucial role in ensuring compliance with regulatory and industry standards. As part of their commitment to providing quality solutions, Chemique has supported Gilcrest with comprehensive adhesive testing designed to meet manufacturing and industry safety standards. This includes adherence to ISO cleanroom compatibility standards and FM approvals for fire resistance and structural integrity.

Gilcrest holds numerous industry-recognised qualifications and memberships, serving as a testament to the dependability, safety, and reliability of their comprehensive product range.

Chemique also provides ongoing technical and engineering support through its Total Service Package, which includes equipment recommendations, regular adhesive deliveries, performance checks, equipment installation, training, and maintenance services, such as annual servicing of Gilcrest’s adhesive pump systems and related equipment.

Long-Term Partnership & Future Growth Plans

Over the years, Chemique’s reliable adhesive solutions and expert technical advice have helped build a strong and trustworthy partnership with Gilcrest Manufacturing. Supported by Chemique’s rigorous internal testing, this collaboration has demonstrated significant improvements in efficiency, enhanced lamination quality, and the creation of durable, long-lasting bonds, enabling Gilcrest to manufacture high-quality composite panels for multiple industries.

In recognition of this continued success together, Gilcrest recently signed a new three-year sole-supply agreement, dedicating both of their production lines to Chemique’s Solfre polyurethane adhesive range.

Mark Souch, Head of Manufacturing at Gilcrest, commented, “Chemique's solution was a perfect fit for our needs. The team's knowledge and recommendations were invaluable at every step, and they were able to recommend an adhesive and the most suitable application equipment for our exact requirements. We look forward to working with them again in the future."

CONTACT

Thomas Hardt

Chemique Adhesives & Sealants Ltd

thardt@chemiqueadhesives.com

www.chemiqueadhesives.com

+44 1922 459321

Friday 10 October 2025 / file under Pharmaceuticals | Food and Beverage | Engineering | Construction | Automotive | Architectural