Rigorous Testing and Certification for Drum Handling Equipment

St Clare Engineering is an established leader in the manufacturing of drum handling equipment

Our Grab-O-Matic drum handling forklift truck attachments demonstrate our commitment to quality, safety and compliance. Our products are not only robust, but are also backed by rigorous testing and certifications, ensuring safety and reliability for customers moving drums in a range of industries.

Safe Working Load (SWL) certification

Safe Working Load (SWL) certification is an official validation process that confirms the maximum load a piece of lifting equipment or accessory can safely handle under specific conditions. SWL is defined as the maximum load that equipment can safely lift, lower, move, or suspend during normal operation, as assessed and certified by a competent person.

SWL certification is a critical safety validation process:

• Safety: it ensures equipment is not overloaded, reducing the risk of catastrophic failure and injury.

• Legal compliance: it helps employers and operators meet regulatory requirements and avoid legal consequences.

• Operational efficiency: SWL facilitates safe load planning and distribution, preventing imbalances and equipment damage.

SWL Certification involves

Proof Load Testing: our drum handling forklift truck attachments undergo proof load testing to verify that they can safely withstand the claimed forces without permanent deformation or failure. This process is essential for product validation and compliance with safety standards.

Documentation: after successful testing, a certificate is provided, detailing the SWL and confirming that the equipment meets the required safety standards. This certificate is often accompanied by a sticker or plate affixed to the equipment for easy identification.

While SWL is still widely recognised, especially in the UK, the term has been largely replaced in international standards by Working Load Limit (WLL) for lifting accessories. Both SWL and WLL refer to the maximum safe load, but WLL is now the preferred term in most formal contexts due to greater clarity and legal precision

Lifting Operations and Lifting Equipment Regulations 1998

The Lifting Operations and Lifting Equipment Regulations 1998 (LOLER) establish safety standards for lifting equipment in workplaces, including drum handling equipment. These regulations apply to employers, self-employed individuals, and anyone controlling lifting equipment.

Key LOLER Requirements

1.Thorough examinations:

• Drum handling forklift truck attachments must undergo mandatory inspections by a competent person every 6-12 months.

• Inspections assess wear and tear, operational fitness and safety, with detailed reports outlining necessary repairs or replacements.

2. Equipment suitability:

• Attachments must be compatible with the forklift truck and suitable for the specific drum or barrel type (e.g., steel, plastic, ribbed, or smooth-sided drums).

• Design factors like grip mechanisms (e.g., waist grippers, rim grips) must align with drum specifications to prevent damage or instability.

3. Safe use and maintenance:

• Daily pre-use checks by operators are recommended, including verifying secure attachment, checking for obstructions and confirming intended use.

• Repairs or replacements (e.g., play in moveable parts) should be addressed immediately after inspections to minimise downtime.

4. Risk Mitigation:

Employers must ensure lifting operations are planned by competent personnel, and risks like load weight, environmental conditions and operator protection are evaluated.

LOLER and the supporting Safe Use of Lifting Equipment Approved Code of Practice (ACOP) require that lifting equipment must be of adequate strength for the proposed use. All lifting equipment, including accessories, must be clearly marked to indicate their safe working load (SWL).

Testing and certification for Grab-O-Matic fork truck attachments

All Grab-O-Matic drum handling fork truck attachments are fully inspected and tested before they leave our factory. They are issued with a test certificate confirming that the equipment complies with the current legislation and LOLER regulations for lifting equipment, and the equipment is clearly marked with its Safe Working Load.

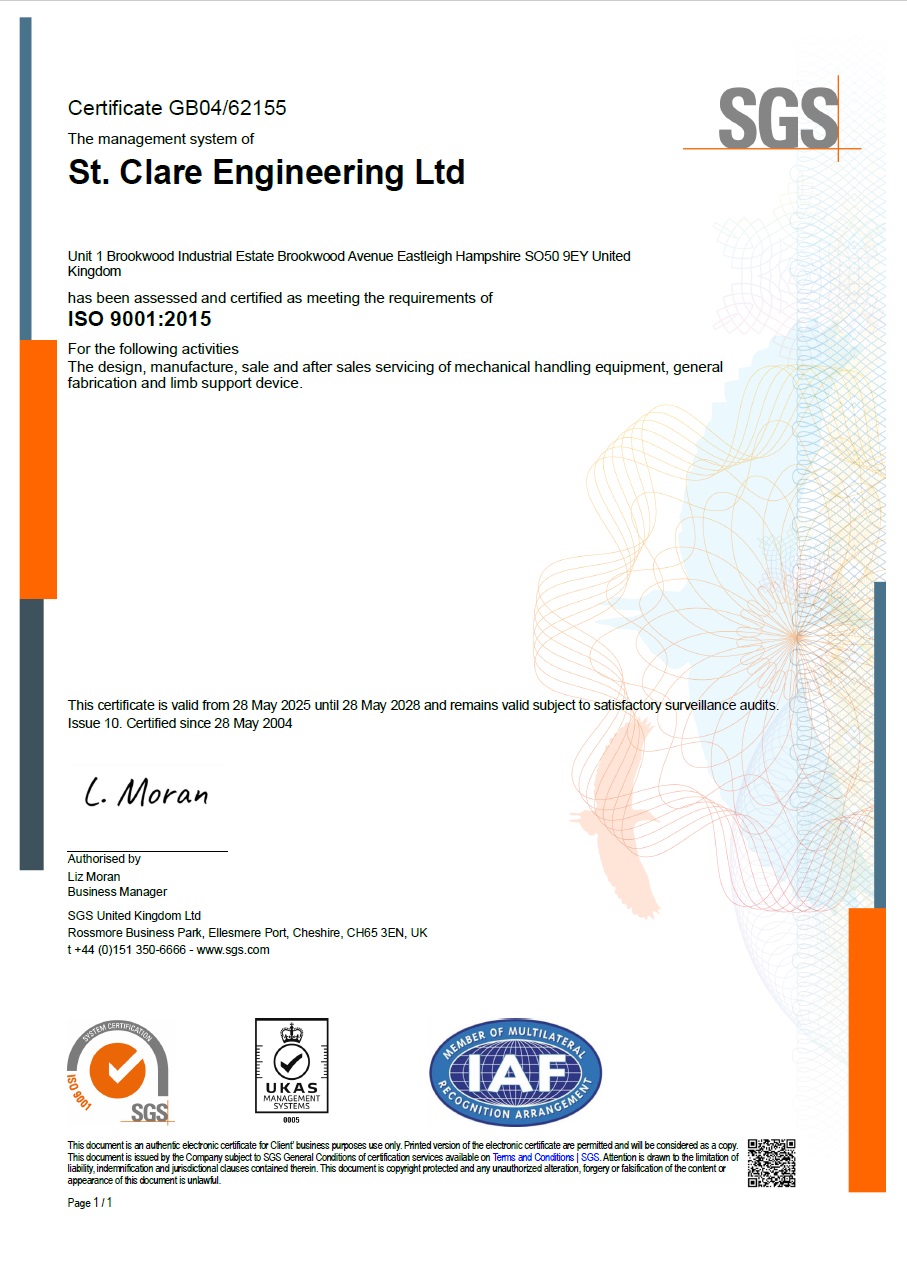

ISO 9001 certification for quality management

St Clare Engineering has just completed a recertification audit under ISO 9001:2015, confirming our continued commitment to quality management.

ISO 9001 is a globally recognised standard which helps organisations to improve their performance, meet customer expectations and demonstrate their commitment to quality. Its requirements define how to establish, implement, maintain, and continually improve a quality management system (QMS).

“Implementing ISO 9001 means your organisation has put in place effective processes and trained staff to deliver flawless products or services time after time.”

Guarantees on our drum handling forklift attachments

All Grab-O-Matic drum handlers are issued with a 12-month warranty against workmanship defects. Our high-quality manufacturing processes, use of robust materials and our 100% testing and inspection policy before goods leave our factory mean that we have an extensive record of many years without any customer returns due to defects.

If our drum handling forklift truck equipment is returned annually for an inspection service and re-test, our standard warranty is extended for a further 12 months from date of service/testing.

EC declaration

Along with the Test Certificate all new Grab-O-Matics are CE marked and issued with the appropriate EC Declaration of Conformity.

Uncompromising quality and compliance

St Clare Engineering has a long-standing reputation (since 1959) for the UK manufacture and supply of high-quality drum and barrel handling equipment, with a strong focus on safety, quality engineering and customer support.

With rigorous testing and adherence to international standards, we are a trusted partner for businesses seeking reliable drum handling solutions. Our proactive approach to maintenance and safety ensures that customers receive not only top-tier products but also the support needed to maintain operational excellence.

Please contact us for more information about St Clare Engineering and the best way to handle drums using our forklift truck drum handling attachments and equipment.

CONTACT

Andy Bow

St Clare Engineering Ltd

sales@stclare-engineering.co.uk

www.stclare-engineering.co.uk

+44 23 8064 3402

Tuesday 3 June 2025 / file under Automotive | Chemical | Engineering | Metals | Oil | Pharmaceuticals