Introducing the Mecmesin Rice Texture Analyzer

Revolutionizing Quality Control for Rice Manufacturers

In the world of rice manufacturing, delivering consistent, high-quality products is the ultimate goal. One of the most critical factors that influence the success of rice products is texture. The Mecmesin Rice Texture Analyzer is here to redefine how rice manufacturers perceive, evaluate and perfect rice texture—a crucial aspect of achieving excellence in the industry.

The texture of rice directly impacts consumer satisfaction and brand reputation. That's why understanding, quantifying and optimizing rice texture is a vital part of the manufacturing process. Ensuring that every batch meets the desired texture is not just an aspiration; it's a necessity.

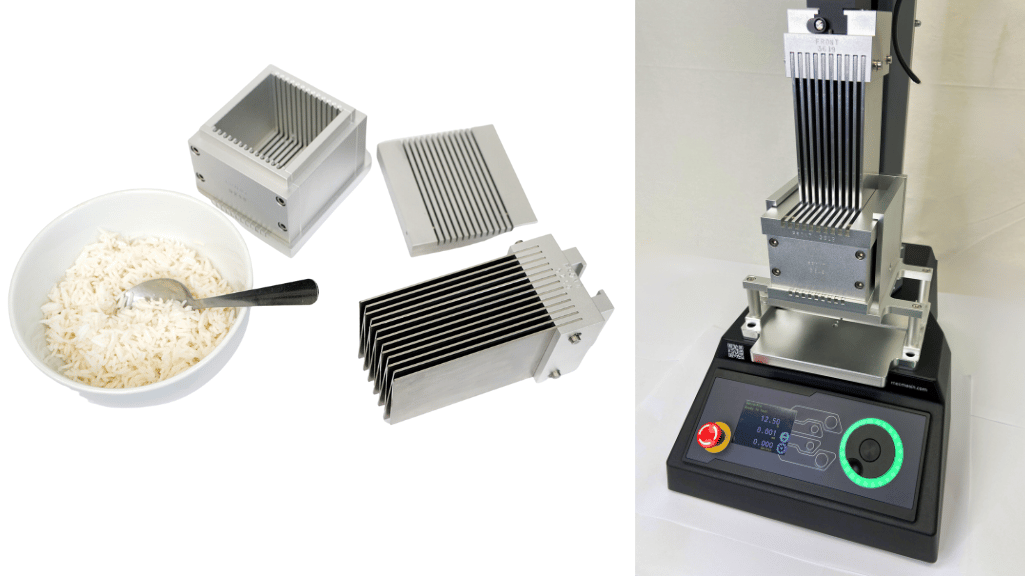

The Mecmesin Rice Texture Analyzer

This Rice Texture Analyzer is a bench-top, software-controlled instrument specifically designed to measure the sensory mouthfeel of cooked rice and other foods with unmatched precision. It replicates the natural bite and chewing action, ensuring that the results correlate precisely with the established Texture Profile Analysis (TPA) parameters that define mouthfeel.

When equipped with a Kramer compression-shear fixture, this advanced system captures a comprehensive set of data points, enabling users to deep dive into the intricacies of rice texture.

Powered by VectorPro Software

At the heart of this technology is our VectorPro software—a sophisticated tool that orchestrates the Texture Analyzer's operation, in accordance with your preset instructions. It not only controls the equipment to apply forces on the test sample but also acquires data and automatically calculates results that align with the correct sensory qualities.

Unlocking key texture quality attributes

The Mecmesin Rice Texture Analyzer empowers rice manufacturers in several critical ways:

• Benchmark and compare rice varieties: Use the system to quantifiably benchmark and compare the texture of different rice varieties. This capability aids in optimizing the cook profile, which, in turn, serves as a valuable guide for consumer preparation instructions.

• Consistency assurance: The system provides a powerful means of ensuring the consistency of supplied raw grains—a vital aspect of maintaining product quality.

• Evaluate harvesting variations: Assess the impact of variations in harvesting, such as variations in protein and carbohydrate levels, which significantly influence the final texture during preparation.

• Measuring firmness, stickiness, and adhesiveness: Analyse firmness by examining the peak compression force during the complete bite cycle. Evaluate stickiness and adhesiveness, crucial parameters in determining consumer satisfaction.

Elevate your rice manufacturing process

In the competitive landscape of rice manufacturing, precision is the key to success. The Mecmesin Rice Texture Analyzer empowers rice manufacturers to fine-tune their processes, optimize product quality, and ensure that every grain of rice consistently meets the highest standards.

CONTACT

Sharon Smorenburg

PPT Group UK Ltd - trading as Mecmesin

info@mecmesin.com

www.mecmesin.com

+44 1403 799979

Friday 13 October 2023 / file under Engineering | Food and Beverage