Guardian Glass Make Thickness Gauge Investment

Inspection Systems has worked with Guardian glass for over 15 years delivering their mainstay product Eagle-I at the cold end of production

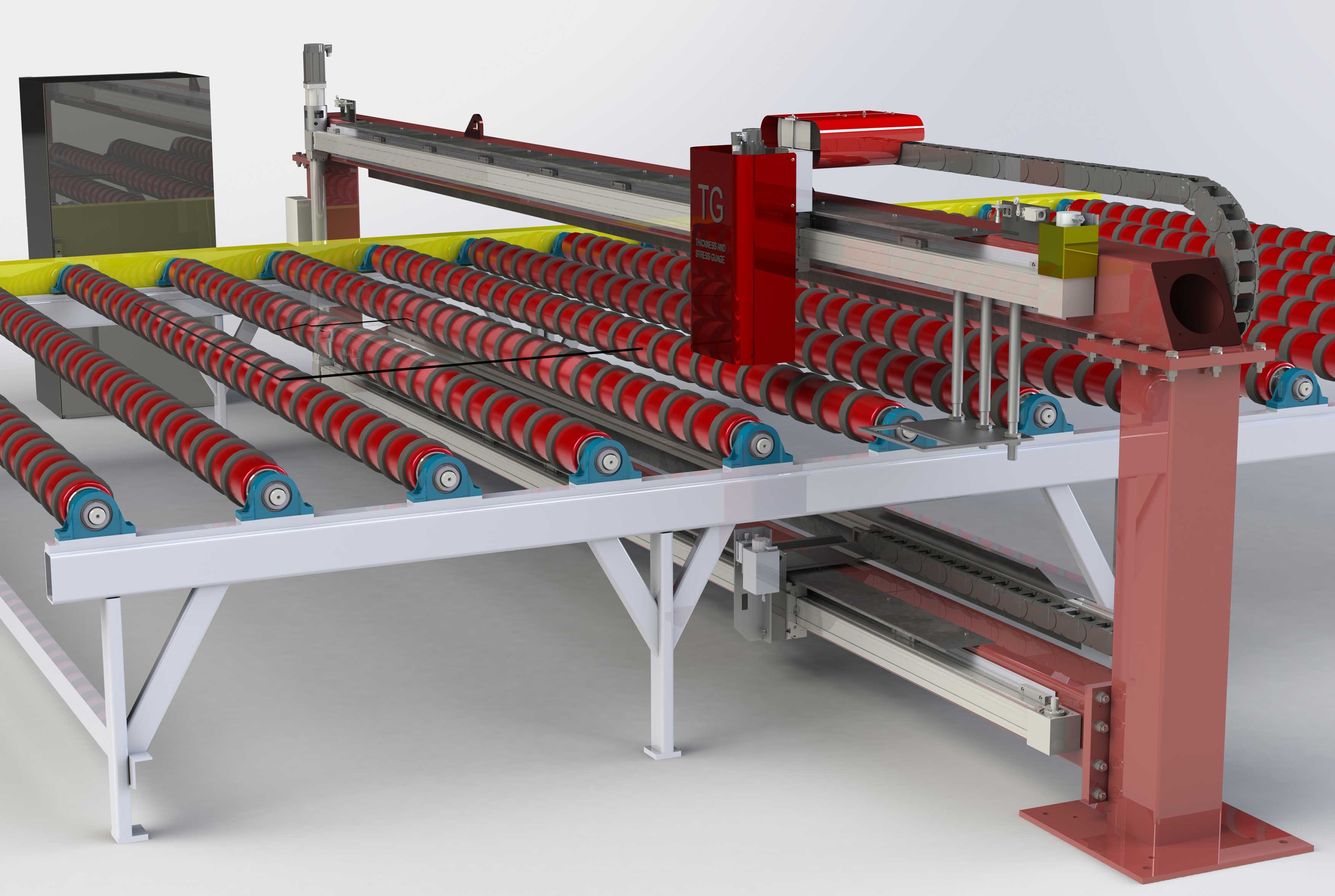

Recently with the next generation of products, Guardian required an inspection system for measuring both the thickness and stress of their float glass.

They turned to Inspection Systems as our Thickness Gauge provides a flexible and innovative approach that has enabled Guardian to adapt the system and software to their needs. After a successful pilot, they are deploying this system at multiple sites.

About Inspection Systems

Inspection Systems has worked in float glass inspection since the late 1980s and the Eagle-I system was one of the first cut plate glass inspection systems brought to market.

We now have over 80 automated vision systems across 6 continents, serving clients such as the Pilkington NSG Group, Guardian Industries Corp, Cardinal FG, AGC North America and the PFG Group.

Our equipment is integrated to plant from companies such as Grenzebach, Bottero, Bystronic and the ICAP Group and offers functionality ranging from the measurement of powder particles to jumbo plates and from the automatic rejection of bad glass to robot stacking of good glass.

Cut plate Inspection; Mirrored glass Inspection; Interleavant powder coverage measurement; Portable Interleavant powder coverage measurement; Hot & Cold Thickness Gauge Measurement.

CONTACT

Stephen Adie

Inspection Systems

stephen@inspection-systems.co.uk

www.inspection-systems.co.uk

+44 161 947 9111

Friday 19 August 2022 / file under Architectural | Construction | Engineering | Technology