Chemique Adhesives Provides The Perfect Bonding Solution For UK Manufacturer Of Fire Rated Door Systems

For over 35 years Chemique Adhesives has always been committed to supporting its customers by providing technical advice and offering innovative adhesive solutions for specific production requirements

A customer that has benefited from this commitment is Solidcor, a manufacturer of fire rated door systems based in Chesterfield, Derbyshire.

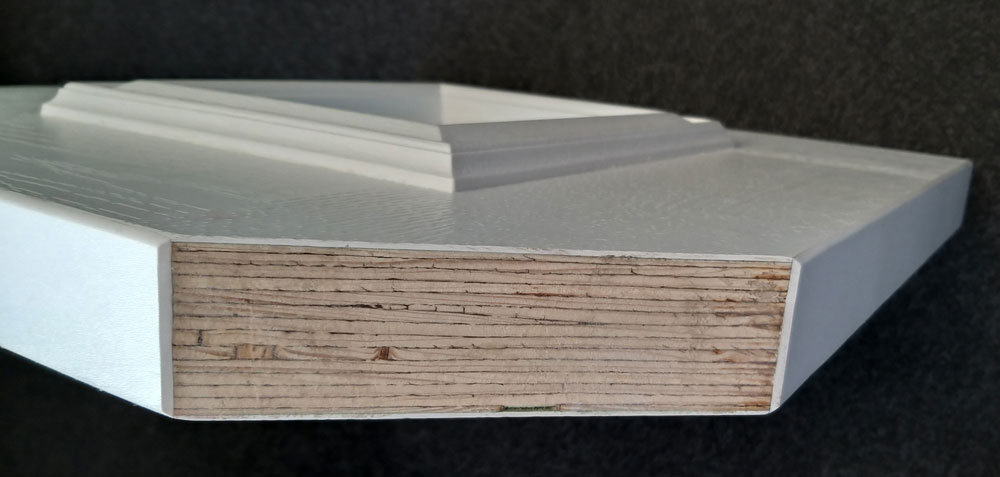

Established in 2020, Solidcor specialises in fire rated entrance doors for both re-fit and new build markets. The company was previously outsourcing their door systems but decided to take full control of their production processes and create their own manufacturing facility.

“Solidcor contacted us to see if we could assist in providing an application and adhesive process that could meet their stringent fire resistance testing requirements when manufacturing fire rated doors,” said Bob Lovegrove, Chemique Adhesives Business Development Manager. “As solid timber core doors and coloured skins have grown in popularity, we had recently developed an adhesive ideal for this application that provides a superior bond strength at a competitive price,” explained Bob.

Samples of the solid timber core doors to be bonded were tested in the laboratory by the technical team at Chemique Adhesives and the test results confirmed that a one component, polyurethane adhesive would be an ideal solution.

“This technically advanced adhesive is from our Solfre range of laminating adhesives and has been specially developed to meet the demands of Solidcor’s popular range of solid core doors,” commented Bob. “This next generation adhesive adds so much more to the bond compared to other products on the market, for example, when bonding to difficult substrates with a low surface tension, you can be confident that the bond strength will stand the test of time.”

Depending on volume and output requirements, the adhesive can be applied manually or automatically and Chemique Adhesives offer a variety of application equipment tailored to suit individual needs.

“The solution provided by Chemique Adhesives was exactly what we had been looking for,” enthused Ashley Smith, Operations Manager at Solidcor. “As this was a brand new process for us, we were more than pleased with Chemique’s knowledge and recommendations. As our range of doors have undergone rigorous safety checks including fire, smoke, weather, security, and endurance testing, it was vital that the adhesive used in the manufacturing process met all fire rating requirements and Chemique were able to supply this along with a cost-effective dispensing system,” continued Ashley.

Solfre 3194 has been specially designed for bonding rigid plastic materials such as PVC, ABS and GRP as well as many standard materials such as timber, rigid foam insulation and steel.

“We have established a great working relationship with the Chemique team and have some exciting plans to further improve our production processes, so we look forward to collaborating with them again in the near future,” commented Ashley.

Chemique Adhesives’ Total Service Package includes tailor-made adhesive solutions combined with full engineering and technical support. A team of engineers are on hand to provide regular servicing and support in case of any breakdowns or issues, which can be dealt with quickly and efficiently.

CONTACT

James Thorpe

Chemique Adhesives & Sealants Ltd

james.thorpe@chemiqueadhesives.com

www.chemiqueadhesives.com

+44 1922 459 321

Tuesday 31 May 2022 / file under Chemical | Construction | Engineering | Safety