Chase International Helping To Improve Waste To Energy Plant Availability

In waste to energy plants replacement thermowells are seen as a consumable item, however the costs can mount up

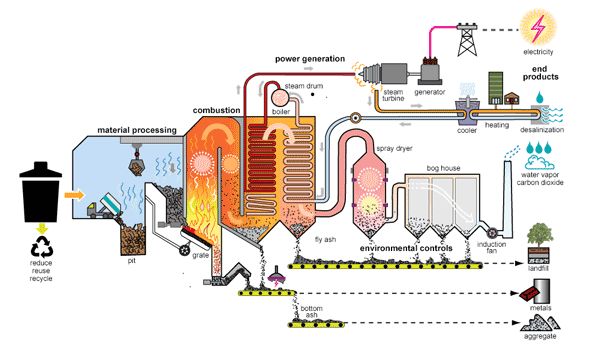

Waste to energy plants burn waste at temperatures up to 850°C to 900°C. Some modern plants, in order to completely burn up materials with a higher combustion temperature, achieve temperatures around 1650°C. Such high temperatures convert most metals and glass to inert ash and reduce the waste to less than 5% of it’s original volume.

The temperature of the furnace is critical to the operation of the plant and must be monitored accurately. This means that at least three measuring points are required, and they must be located directly above the flame.

Due to the high temperatures, the unknown content of the waste, the corrosive gases and abrasive ash in the furnace the devices measuring the temperature of the furnace have a short lifespan. The RTDs or thermocouples, used to measure temperature, are protected by thermowells, however some thermowells can have a lifespan of weeks or, in some cases, days.

The economics of waste to energy plants is based on both disposal of waste and generation of electricity. Shutting down the furnace to change thermowells is both expensive and inconvenient. Critical shutdown due to thermowell failure is a major issue for an operator.

CHASE work with experts, at BKW Instruments, in the design and development of waste to energy replacement thermowells, specifically to improve mean time between failures, simplify the replacement process and thus save money and reduce operational disruption.

These thermowells have been tried and tested in the UK and are available, from CHASE, for Waste to Energy plants around the world.

CONTACT

Vanessa Holt

CHASE International Limited

source@chaseint.co.uk

www.chaseint.co.uk

+44 1925 755221

Tuesday 15 March 2022 / file under Energy | Engineering | Environmental | Power | Recycling