Odours Away For Dairy Effluent Thanks To New Landia Mixing System

Industrial effluent treatment plant specialists, FLI CAP Technology have brought in Landia’s AirJet aeration system to a major dairy products manufacturer in the North West of England

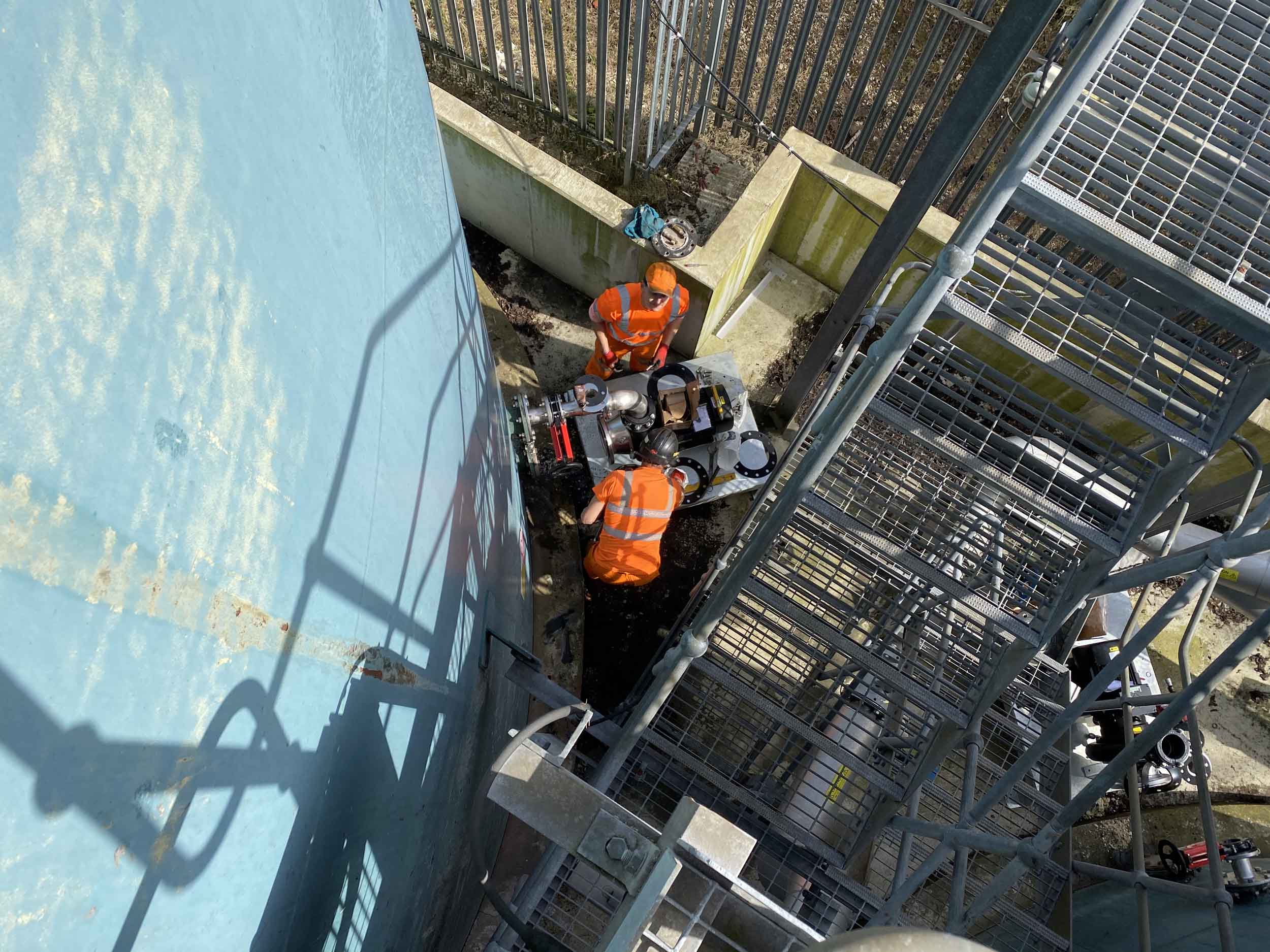

A retrofit installation, which had to be achieved in an extremely tight space, has greatly enhanced dairy effluent mixing to enhance the overall process, and importantly, prevent odours. The AirJet also removes the cost of adding chemicals or using energy-burning blowers.

Incorporating Landia’s long-proven chopper pump, invented by the company in 1950, the AirJets are installed on two 7m high, 8.5m diameter glass-lined steel tanks (each 370m3).

John Hampson, Director at FLI CAP Technology, said: “Based on many years’ first-class experience with Landia pumps and mixers, we are always confident that our customers will be pleased with the results – and this retrofit was no exception”.

He added: “The confined spaces made installation very awkward indeed, but Landia rose to the challenge, working closely with our team to devise a way of getting the AirJets down through a maze of pipework and obstructions”.

The AirJets, with their venturi nozzles and 18.5 kW-1500 rpm pumps were installed by Landia’s Kieran Hilton and Jack Foster – both of whom served their apprenticeships at the pump and mixer manufacturer after attending Sir John Talbot's School in Landia’s home town of Whitchurch in Shropshire.

Howard Burton from Landia, said: “It is very heartening to see our young engineers come through the ranks to carry out such excellent work – giving a company with the calibre of FLI CAP Technology total assurance that the Landia team will get the job done on time and within budget”.

CONTACT

Paul Davies

Landia UK Ltd

info@landia.co.uk

www.landia.co.uk

+44 1948 661200

Friday 16 July 2021 / file under Agriculture | Engineering | Food and Beverage