Borger Waste Salmon Crush For Isle Of Lewis Biogas

A Multicrusher made by Borger is playing a key role in the continuing success of an award-winning waste-to-energy operation in the Outer Hebrides, Scotland

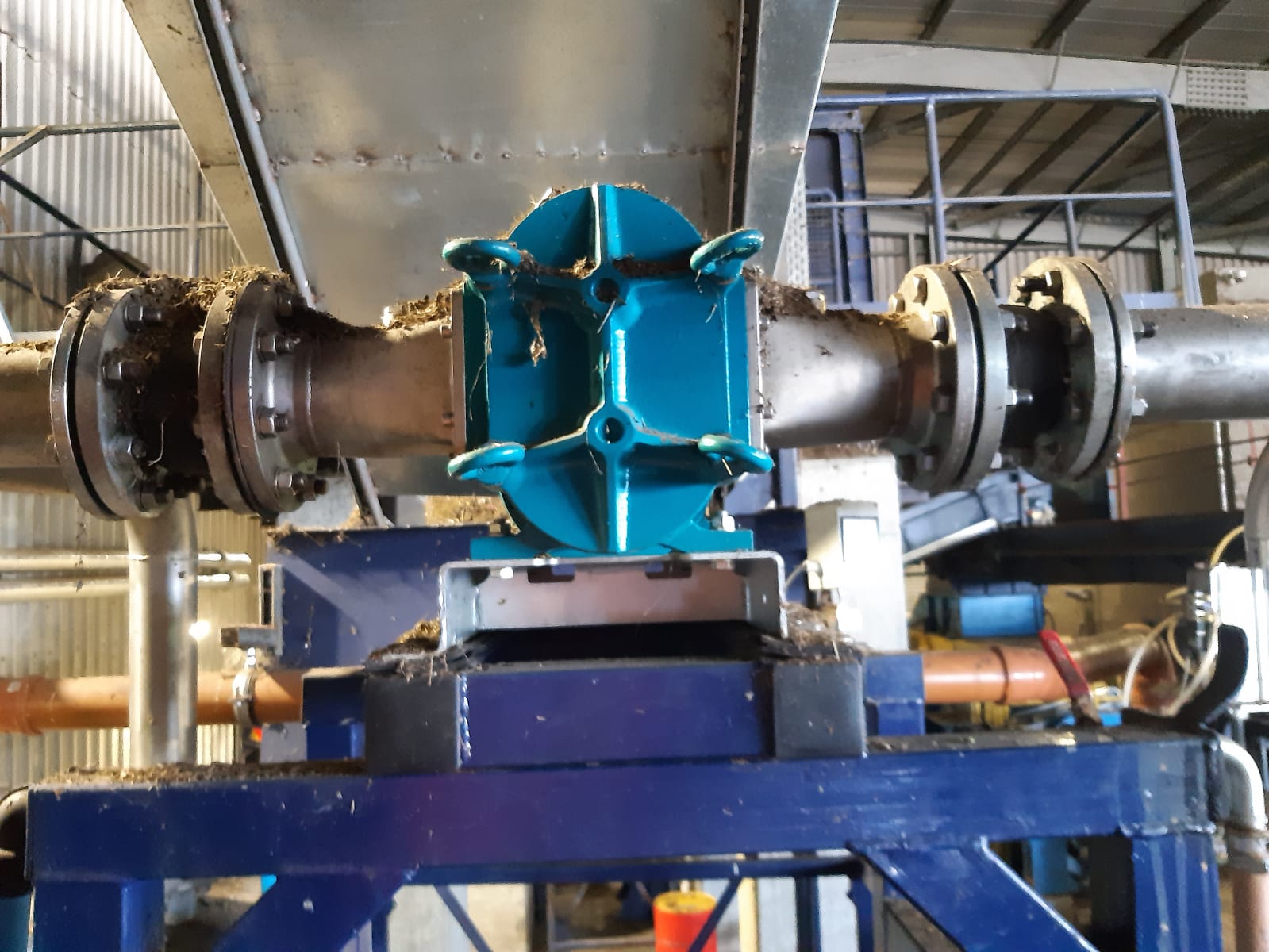

At Stornoway’s Creed Integrated Waste Management Facility (IWMF) on the Isle of Lewis, the Borger Multicrusher consistently chops a 7-cubic ton batch per shift of coarse waste salmon. This has enabled the facility to integrate the fish with household food waste and garden waste for its AD/biogas process.

Crucially guaranteeing the shred of waste salmon to meet BSI PAS 110 regulations & EU ABP regulation 1774/2002 [5a] for the safe use of digestate as a renewable fertiliser, the Borger Multicrusher cuts the waste to the required maximum particle size of 12mm.

This vital cog in the process has helped Comhairle nan Eilean Siar (the Local Authority for the Western Isles), together with its partners, The Scottish Salmon Company, Pure Energy Centre PEC, and Community Energy Scotland, win the prestigious Scottish Environment Business VIBES award.

Donnie Macmillan, Plant Manager at the Creed facility, said: “Borger’s Multicrusher works extremely well for us in a very harsh environment. Some salmon waste can be quite tough and abrasive, so understandably we see wear on the cutters during our inspections, but that’s perfectly understandable”.

He added: “Importantly, the Borger unit helps us meet all of our PAS 110 requirements, which is all part of what we set out to achieve here - optimising the methods of managing waste - in this case not sending waste salmon to landfill sites, and not having to have it transported off the island”.

Based on the proven design of the Borger Rotary Lobe Pump, the twin-shaft Multicrusher homogenizes the waste salmon to facilitate the pumping and pasteurisation process at Creed, ensuring that downstream equipment can operate smoothly. By inserting individual blade disks and defining the direction of rotation of the shafts, operators have the flexibility to choose which way the pumped medium flows. Various blade widths and cutting profiles determine the final cutting yield.

David Brown, Borger UK’s Managing Director, commented: “We are very proud to play our part at Creed. It rightly deserves all the praise it gets for showing what can be done to protect the environment and reduce carbon footprint with good practice, forward-thinking and hard work”.

Managing waste from the island’s population of approximately 22,000, the Creed IWMF has grown steadily to include a combined heat and power plant (CHP), electric boiler and thermal store, a wind turbine and a hydrogen system comprising electrolyser, storage and refuelling station, and a 960m3 AD/biogas plant.

Some of the electricity generated by the CHP is used to produce hydrogen and oxygen. This is captured, compressed and delivered to the salmon hatchery, where oxygenation is essential.

Hydrogen is used in a small fuel cell to provide electricity to the remote site, which sometimes suffers from electrical network failures. Previously, back-ups were provided by ageing diesel generators, meaning higher CO2 emissions and delivery costs. The hydrogen system at Creed also includes a refuelling station, where some of the hydrogen is used to refill a dual-fuel Refuse Collection Vehicle (RCV) operating on hydrogen/diesel.

CONTACT

David Brown

Borger UK Limited

uk@boerger.com

www.boerger.com

+44 1902 798977

Friday 19 February 2021 / file under Agriculture | Engineering | Environmental | Utilities