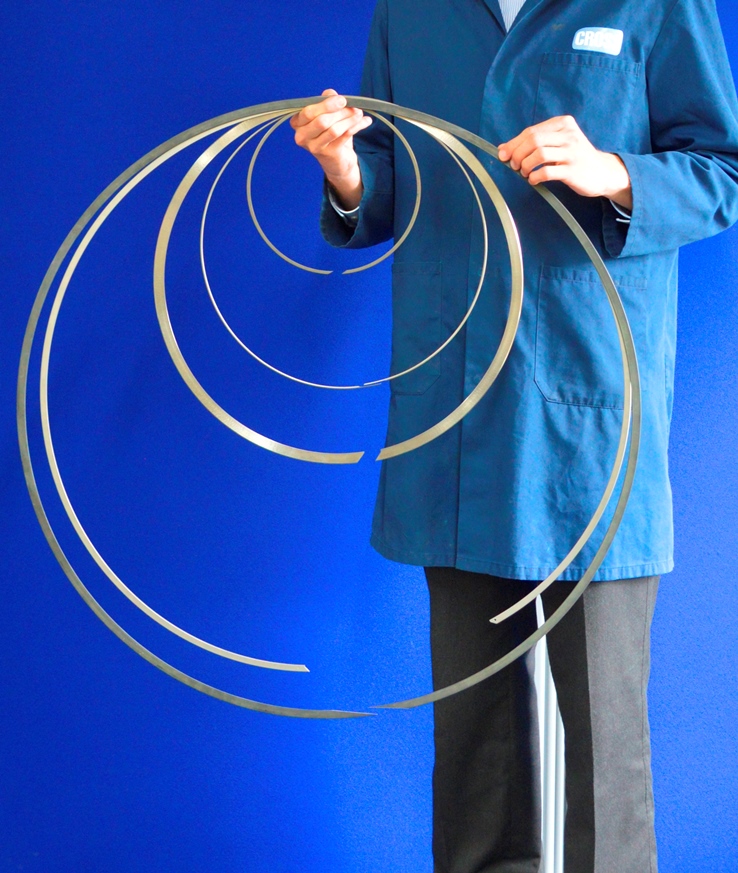

Rugged And Lightweight Compressor Blade Retaining Rings For Aerospace Engines

Specially designed retaining rings are a well proven method of retaining compressor and turbine blades to the rotating drum in modern aircraft engines

Combining a speedy assembly technique with reliable blade retention. Holding the blades in place at high speeds and temperatures demands a rugged and lightweight ring design.

To meet these challenges, Cross has developed a method of transforming wire made of difficult alloys such as Waspaloy, Titanium, Inconel 718 and X750 into the required section for engine geometry. This efficient and environmentally sound process creates negligible waste when compared to traditional machining techniques. It can also offer significant improvements in mechanical properties over rings machined from sheet or forgings, including a very precise circumferential fit and enough spring to hold them in position at operating temperatures up to 800°C.

Rings can be dynamically balanced for optimum rotational performance and produced with a range of gap configurations, many of which have been designed by Cross to meet different engine manufacturers’ specifications.

Blade retaining rings are a fast-growing sector in Cross’s comprehensive product offering, which includes high temperature sealing rings, blade damping rings, brush seals and other high-integrity sprung components for aircraft engines, gas and steam turbines, vehicle turbochargers, control valves and other challenging applications.

CONTACT

Richard Cross

Cross Manufacturing Co (1938) Ltd

mail@crossmanufacturing.com

www.crossmanufacturing.com

+44 1225 837000

Thursday 31 October 2019 / file under Aerospace | Engineering