Metal Contamination Solutions From Bunting Magnetics At VICTAM 2019

Bunting Magnetics is exhibiting a range of metal contamination solutions on stand A029 at the VICTAM International 2019 exhibition (Cologne, Germany June 12 – 14)

The range of Magnetic Separators and Metal Detectors both identify and capture problematic metal that is potentially dangerous to consume and can also cause explosions.

Bunting Magnetics is one of the world’s leading designers and manufacturers of magnetic separators and metal detectors for the feed, grain, cereals and food industries.

Metal contamination is a common problem in most processing operations. The metal originates during farming and transportation and is often introduced into the process with the raw material. Metal contamination is also introduced from plant breakdown and wear during the process.

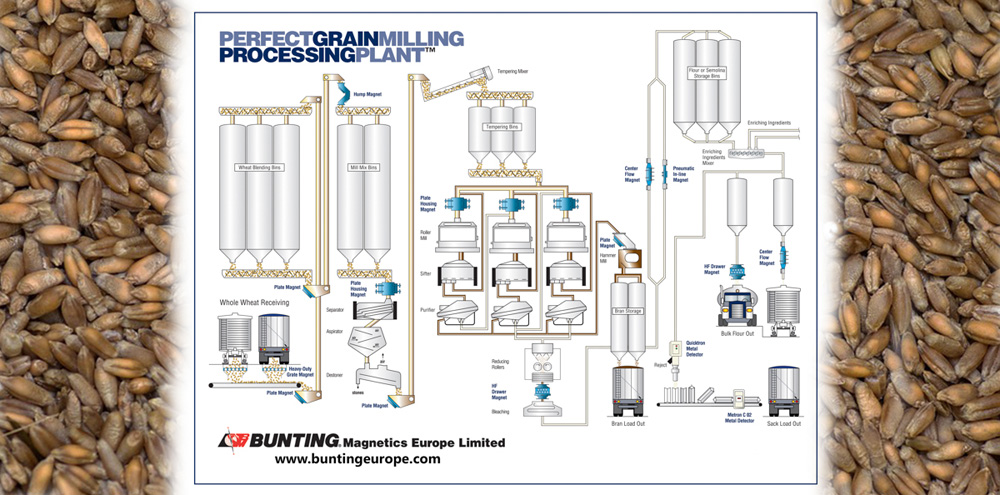

Successfully detecting and removing metal contamination requires the installation of magnetic separators and metal detectors at critical stages within the process. The combination of different technology and designs enables optimum metal removal. This prevents damage to processing plant and also ensures a high-quality end product.

Magnetic Separators Removing Ferrous Metals

Magnetic separators are commonly installed early in the process to capture and remove ferrous metal contamination. On the stand at VICTAM, Bunting is displaying a wide range of high intensity, Neodymium Rare Earth Magnetic Separators including Drawer Filters, Plate Magnets, Bullet Magnets, and Pneumatic In Line Magnets (PIMS).

Detecting Metal Contamination

Later in the process, often during and after the packing stage, the material is passed through a Metal Detector. This identifies any rogue metal contamination, whether ferrous or non-ferrous in nature. Bunting is demonstrating a QuickTron free-fall Metal Detector on the stand, showing how small particles of metal is both detected and automatically removed.

Once packed, the finished product is often conveyed through a final Metal Detector as a final check and additional details will be available on the stand.

Solving Metal Contamination Problems

"Although we have supplied metal separation solutions to the feed and grain industry for several decades, this is the first time we have exhibited at VICTAM,” said Dave Hills, Bunting’s Head of Sales. “Our magnetic separator and metal detector designs have developed over time to suit the industry’s arduous environment. We are looking forward to helping companies solve problems with proven technology.”

CONTACT

David Hills

Bunting Magnetics Europe Ltd

sales@buntingeurope.com

www.buntingeurope.com

+44 1442 875081

Tuesday 14 May 2019 / file under Agriculture | Engineering | Environmental | Food and Beverage | Machinery