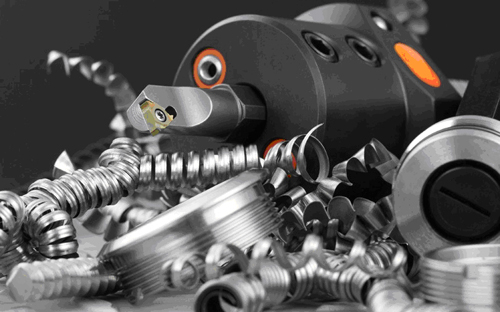

Controlling Scrap And Reducing Costs

McKenna Precision Castings has taken further leaps into reducing the cost of production by re-engineering their manufacturing process

Not satisfied with the already well oiled and refined manufacturing capability the engineering department embarked on a program to totally eliminate scrap in the Aluminium production lines so that they could match the very low scrap rates experienced in the Commercial and Steel lines.

While scrap is inevitable in the casting industry McKenna saw an opportunity, enkeeping with its ethos of ‘Continuous improvement’ to increase its yield. The ‘Scrap review Team’, with clear concise communication within the group, included representatives from the Production, Shop floor and Quality departments and this ensured that every aspect of manufacturing was covered by a convergence of ideas from different view points.

The result is indeed remarkable. Parts are better designed as are tools and jigs; operators have new and better work instructions and training while the process saw modifications in the Assembly and Shell departments so that the knock on effect down the line would be beneficial to the objective of reducing scrap and rework.

McKenna now is in a very strong position to offer its customers a better deal and really turn reduction in scrap into a competitive advantage.

CONTACT

Liberty Gwitira

McKenna Precision Castings Ltd

libg@mckennaprecision.co.uk

www.mckennaprecision.co.uk

+44 1909 541414

Wednesday 14 September 2016 / file under Automotive | Aerospace | Engineering | Gas | Metals | Oil