Functionalised Graphene Ink Opens Door To Innovative Screen Printing Applications

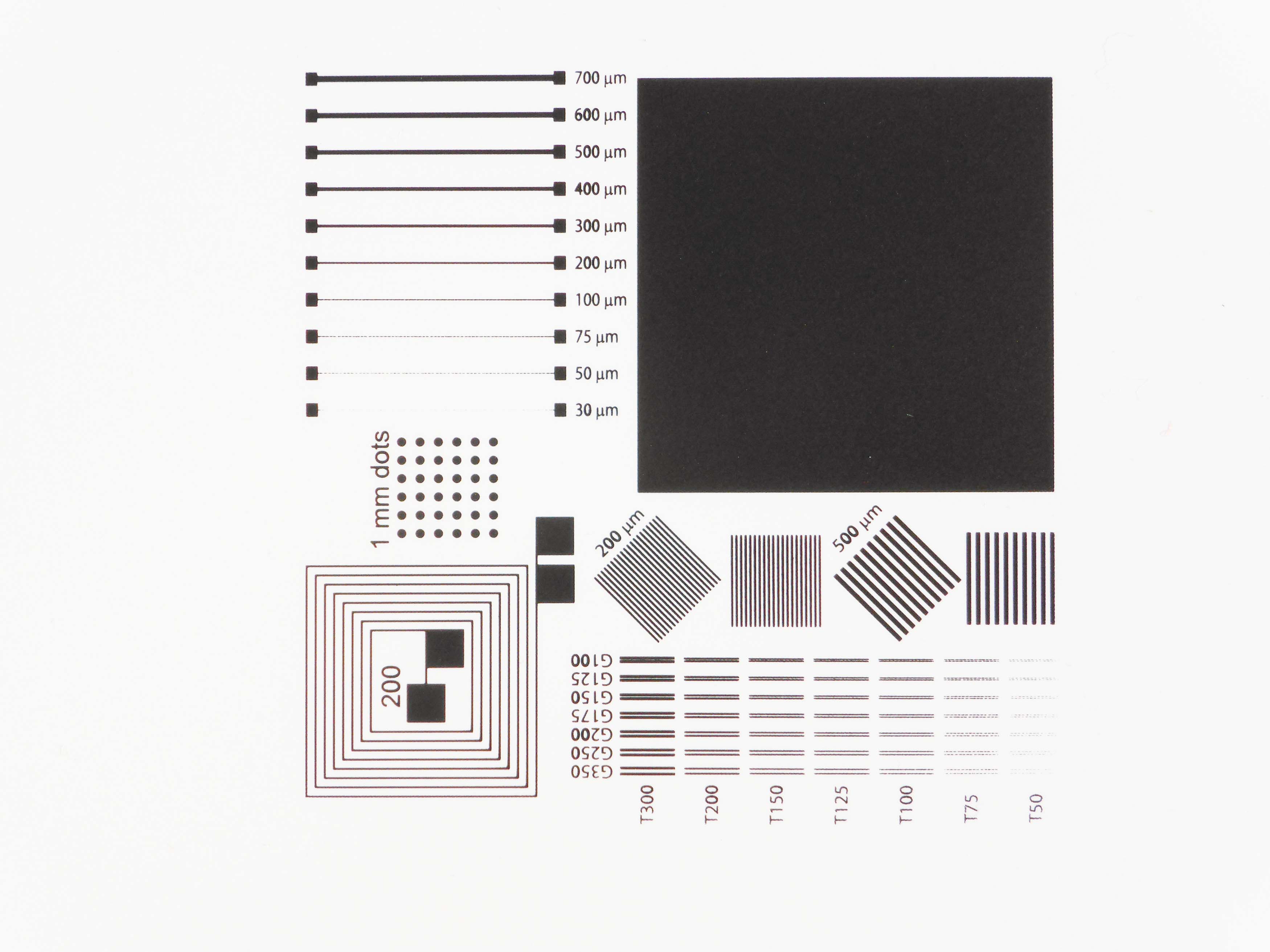

A screen-printable functionalised graphene ink supplied by Goodfellow performs better than normal carbon-based ink

This opens the door to innovative applications that require exceptional electrical conductivity, excellent ink coverage, and high print resolution. Such applications are found in light flexible displays, plastic electronics, printed circuit boards, thin film photovoltaics, sensors, electrodes and OLEDs.

The ink is made with HDPlas® functionalised graphene nanoplatelets and is optimised for the viscosity and solid contents required of semi-automatic and manual screen-printing equipment. Substrates that can be printed include but are not limited to polymers, ceramics and papers.

In addition to the distinguishing characteristics stated above, functionalised graphene ink is:

- Flexible on appropriate substrates

- Metal-free, 100% organic (non-tarnishing)

- Curable at low temperatures

- Environmentally friendly

The ink is fully customisable and can be modified for specific applications. Scientists and printers running trials with the small quantities available from Goodfellow (100g to 1000g) can, if desired, consult with Goodfellow to further tailor performance in order to meet individual needs.

For more information about functionalised graphene ink, go to www.goodfellow.com/news-article/screen-printable-functionalised-graphene-ink/.

CONTACT

Stephen Aldersley

Goodfellow Cambridge Ltd

info@goodfellow.com

www.goodfellow.com

+44 1480 424800

Thursday 1 October 2015 / file under Electronics | Printing