Spiroflow Robust Handling Equipment Built To Survive Stormy Seas

Spiroflow Ltd has helped a major petroleum company make substantial savings on its shipping costs, by manufacturing and supplying handling and conveying equipment

The equipment is for operation on a gas rig located in a region renowned for extreme weather conditions.

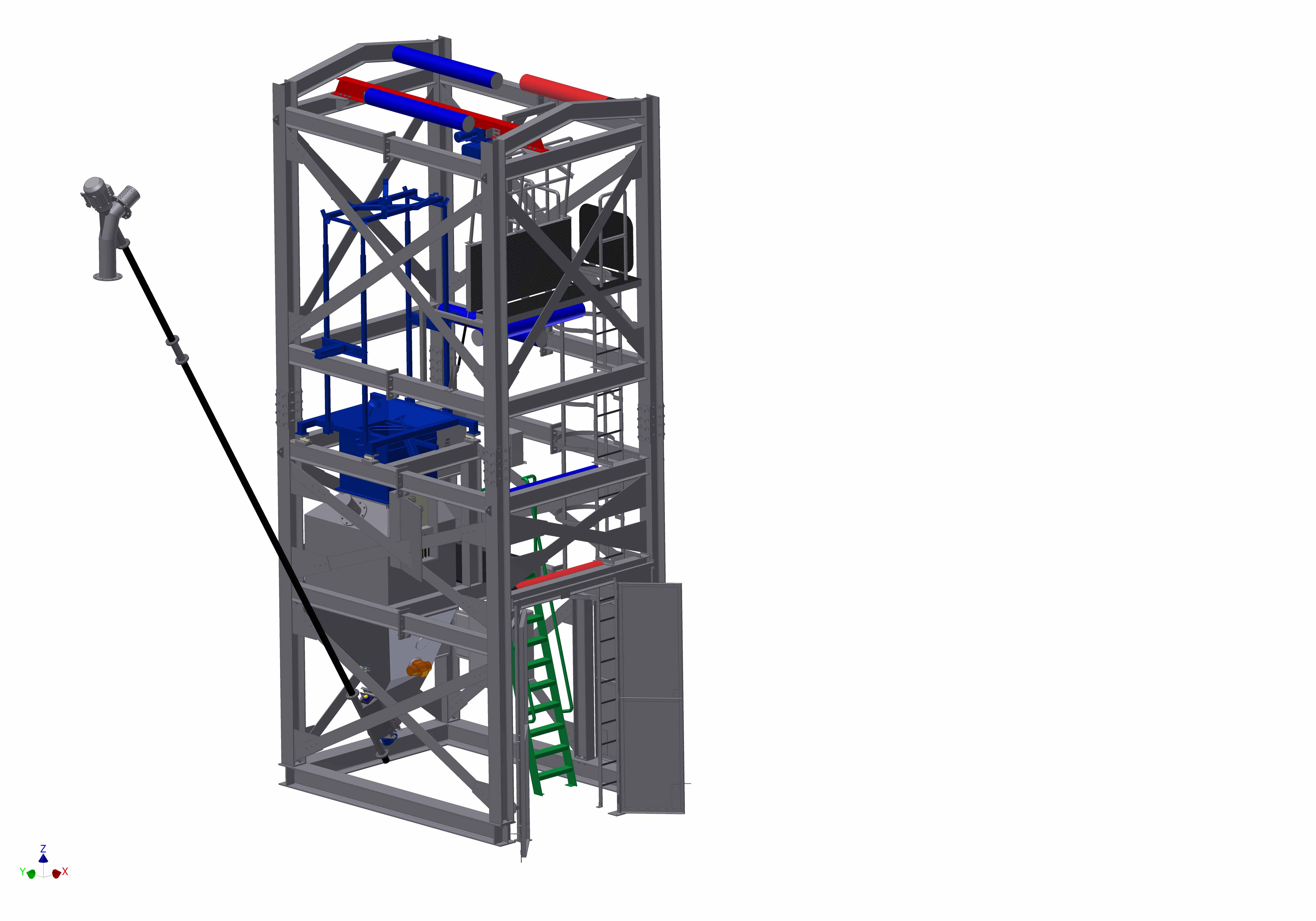

The bespoke project, in collaboration with one of the biggest suppliers to the offshore industry in the world, was for a bulk bag discharger with a hopper, hoist and flexible screw conveyor that were sturdy enough to withstand the most ferocious weather, which could also be operated remotely from the mainland for up to seven days in the event that gas rig workers had to be vacated from the platform because of typhoon warnings.

Spiroflow was contracted to design and build a bulk bag discharger large and robust enough to withstand the elements and safely hold an accumulation of material from the process (which cannot be described due to contractual reasons) so that it could be conveyed safely without human intervention during any time of extremely dangerous weather conditions.

Specialist engineers at Spiroflow took into account the wind loadings to ensure the safety of the heavy duty structure housing the equipment, as the rig was located in an area of the Asia Pacific region where stormy weather is the norm. It also had to strictly conform to safety regulations for working in an explosive atmosphere.

Full design, assembly and testing was carried out in Clitheroe before the system was dismantled, shipped to China and reassembled on the dock before being lifted on to a barge for transportation to the gas rig where it was eventually installed and commissioned – all work carried out by a team of Spiroflow engineers. The company has also agreed an annual service contract with Spiroflow.

Spiroflow’s head of engineering, Chris Brennan, said: “This project presented interesting challenges and required the application of cutting-edge technology. We had to take into consideration structural calculations needed for a typhoon area as well as the movement of the platform caused by the waves. We had to work closely with the customer and end user so our engineers were living on the rig for the duration. We think the end result is of huge benefit to the offshore industry – potentially saving millions in shipping costs - and a major breakthrough in this important sector for us.”

Bulk Bag Dischargers from Spiroflow can be supplied for materials from a wide variety of industries including food, chemicals, minerals and pharmaceuticals as well as the oil and gas sector. They provide an air-tight operation which empties product with the minimum of residue.

Flexible Screw Conveyors can be made for conveying in any direction from horizontal to vertical. They can also be routed around fixed obstacles and equipment. Spiroflow’s conveyor system inherently ensures material is constantly being remixed by action of the rotating auger feeder, which effectively eliminates the risk of product segregation.

Spiroflow’s world-leading products for conveying and bulk handling are designed and built to USDA standard and meet regulatory requirements for transporting and handling materials in potentially hazardous and explosive conditions, such as offshore platforms.

In addition to bulk bag dischargers and flexible screw conveyors, Spiroflow manufactures bin activators, Aero Mechanical Conveyors, Tubular Cable and Chain Drag Conveyors, Vacuum Conveyors, Bulk Bag Fillers, Ingredients Handling and Weighing Systems. The company’s technical and engineering expertise has led to it developing an international reputation for an unrivalled range of products with state-of-the-art control systems.

CONTACT

Tim Cox

Spiroflow Limited

tim.cox@spiroflow.com

www.spiroflow.com

+44 (0) 1200 422525

Monday 8 September 2014 / file under Oil | Machinery | Gas | Engineering