R-TECH Materials Awarded Funding To Model Austenitic Steels For Nuclear Industry

Technology Strategy Board funds £150k feasibility study to develop condition-based structural integrity and life assessment model

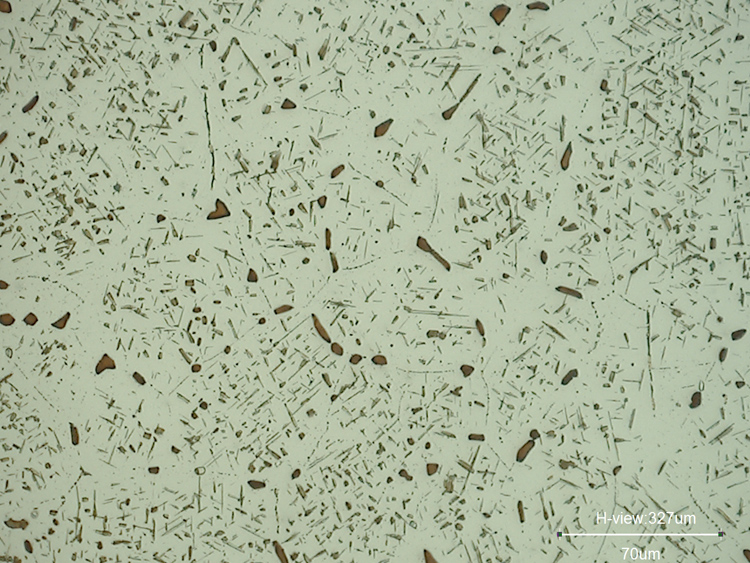

Ex-service stainless steel pipe showing precipitation of sigma phaseR-Tech Materials is celebrating the award of funding from the UK’s innovation agency, the Technology Strategy Board, under their funding competition on “Developing the UK Civil Nuclear Supply Chain”.

The award, made to Metamet Consultants Ltd, part of the R-TECH Materials Group is for a feasibility study to enable R-TECH to develop a condition-based structural integrity and remaining life model for austenitic stainless steels. This is expected to have significant application in the nuclear industry, particularly with respect to life extension of the UK’s ageing fleet of AGR reactors, and also with the new generation of High Temperature Reactors.

This award will enable R-TECH to build on research it has already conducted in conjunction with Swansea University, and develop prototype modelling software for use by plant operators, regulators, designers, builders and materials manufacturers. Although focused initially on the nuclear sector, it is expected that the technology will also be more widely applicable globally across the high temperature process industries.

The Technology Strategy Board has agreed to fund 75% of the total project costs, expected to be almost £150k over the 12-month project life. As well as the work done by R-TECH’s Materials Engineers, a significant contribution will also be made by SES (Europe) Ltd, who partnered with R-TECH in the preliminary research, and are responsible for model development. SMaRT, will be responsible for the mechanical testing programme.

R-TECH Materials Director Dr Tony Franks recognises the opportunity which the TSB funding has opened up:

“This is a massive opportunity for us to build on work which we have previously funded at Swansea University and develop it into a commercial product. Without the support from TSB it is highly unlikely that we would have been able to take this work forward, and certainly not at the rate we now envisage.”

This feasibility study focusses on structural integrity issues arising from the continued life extension of the AGR fleet - in particular with the austenitic steels used in heat exchangers for tubing and supports. Operating in the creep regime, these materials show considerable microstructural development in service, with consequent changes in mechanical properties.

It includes an experimental programme comprising creep, tensile, and impact testing of pre-aged Type 316 steels, with associated metallographic studies. The aims are to assess the potential for a formal method of classifying microstructural development, a model of this development, and a preliminary model of the resultant mechanical behaviour. The deliverables will include demonstration software that estimates remaining creep life on the basis of observed microstructural state, using the preliminary model.

R-TECH Materials is a group of materials testing, analysis and consultancy businesses based in Port Talbot, South Wales, consisting of R-TECH Services Ltd, a UKAS accredited materials testing and analysis business, and Metamet Consultants Ltd, specialists in laboratory-based materials investigations.

SES Europe staff have extensive experience of research for internal purposes, through joint-industry projects and through national and European funded programmes. They can bring to bear 40 years of mechanical testing and modelling in support of structural integrity assessment and life prediction in nuclear and fossil fired power plant and petrochemical equipment, as evidenced by a considerable record of publications.

SMaRT is Swansea Materials Research and Testing Ltd, and has a proven track record in performing test programmes to client requirements, supporting both academic and industrial research.

Feasibility Studies is a single-company or collaborative R&D grant scheme run by the Technology Strategy Board that allows businesses the opportunity to test an innovative idea and its feasibility to be developed and eventually taken to market.

Feasibility studies are a way for companies to carry out exploratory studies which could lead to the development of new products, processes, models, experiences or services. The study could involve for instance investigating the technical feasibility of a new idea. https://www.innovateuk.org/-/feasibility-studies

CONTACT

Dr Tony Franks

R-Tech Materials

tony.franks@metamet.co.uk

www.rtech-materials.co.uk

+44 (0) 1656 748000

Friday 8 August 2014 / file under Nuclear