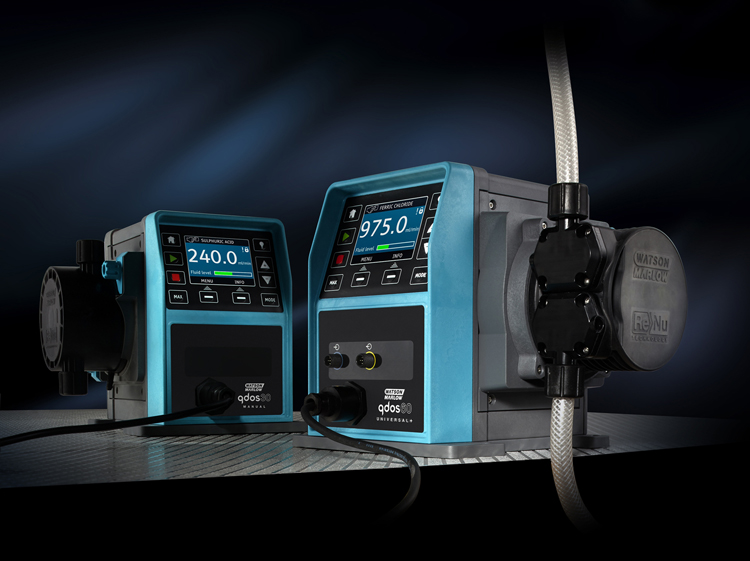

New QDOS 60 Metering Pump For High Accuracy Applications

Following the highly successful launch of the revolutionary Qdos 30 peristaltic metering pump, Watson-Marlow Pumps Group is now introducing the larger Qdos 60 model

This innovative and versatile new pump is designed to save costs in chemical metering applications thanks to its inherent higher accuracy metering. The addition of Qdos 60 expands the range to incorporate flow rates from 0.1 to 1,000 ml/min (0.001 to 15 USGPH) at 7 bar (100psi). Furthermore, simple installation and easy, tool-free maintenance ensure total cost of ownership is minimised.

With the market demanding cost effective systems offering low operational expenditure, Qdos 60 negates the need for ancillaries, boosts productivity and cuts chemical wastage via more accurate, linear and repeatable metering than conventional solenoid or stepper-driven diaphragm metering pumps. As a result, Qdos 60 is able to reduce chemical costs even when metering difficult fluids, or when pressure, viscosity and solids content vary. This capability combines with peristaltic technology to ensures precise, continuous smooth flow for optimal fluid mixing

Typical applications for Qdos 60 include disinfection, pH adjustment and flocculation of drinking water, wastewater and industrial process water, as well as reagent dosing/metering in mineral processing tasks. The new pump is especially suited to chemical metering applications found in larger water treatment plants where flow demand is greater than that provided by the existing Qdos 30 model. Advanced control features include fluid level monitoring, fluid recovery, line priming and intuitive flow calibration.

Driven by ever-higher quality standards, enhanced pump accuracy enables higher concentration chemicals to be used, thus saving on transport costs and driving down carbon emissions targets.

Installing Qdos 60 could not be simpler. This drop-in pump requires no pulsation dampener, strainers or float switches, nor does it require any de-gassing, back-pressure or foot valves. What’s more, the pump meets the demand for low/no upkeep products driven by reduced maintenance budgets. This is because there are no seals or valves in the Qdos 60 flow path to clog, leak or corrode, and there’s no opportunity for vapour lock.

In addition, Watson-Marlow’s patented ReNu pumphead technology provides a single, safely contained component for rapid maintenance without the need for tools. Rapid, straightforward pumphead removal and replacement minimises process downtime and demands no specialist training or technicians.

Ideal for installing in restricted environments or on skids, the pumphead can be configured on the left or right. Intuitive operation is facilitated via a menu-driven interface featuring a 3.5" TFT colour display with high visibility status indication. The keypad and display are positioned for easy access, along with input and output connections.

Engineers will also benefit from the ability to implement simplified system designs. The high suction lift and viscous handling capabilities of Qdos 60 eliminate the need for flooded suction, day tanks and specialist piping schemes. Ultimately, there will never again be a requirement to use a diaphragm metering pump.

CONTACT

Mike Sullivan

Watson Marlow Pumps Group

mike.sullivan@wmpg.com

www.wmpg.co.uk

+44 (0) 1326 370370

Tuesday 1 July 2014 / file under Engineering | Environmental | Utilities