New High Speed Machine Tool Scanning System At Southern Manufacturing 2014

Renishaw, the global metrology specialists, will be exhibiting their advanced engineering products at Southern Manufacturing 2014, from 12 – 13 February at FIVE in Farnborough, UK

On Stand Q90, visitors will have the opportunity to see a range of products which can help companies to improve their manufacturing processes, including gauging systems, machine tool calibration systems, 5-axis measurement systems for CMMs, additive manufacturing systems, and the new SPRINT™ high speed contact scanning system for machine tools.

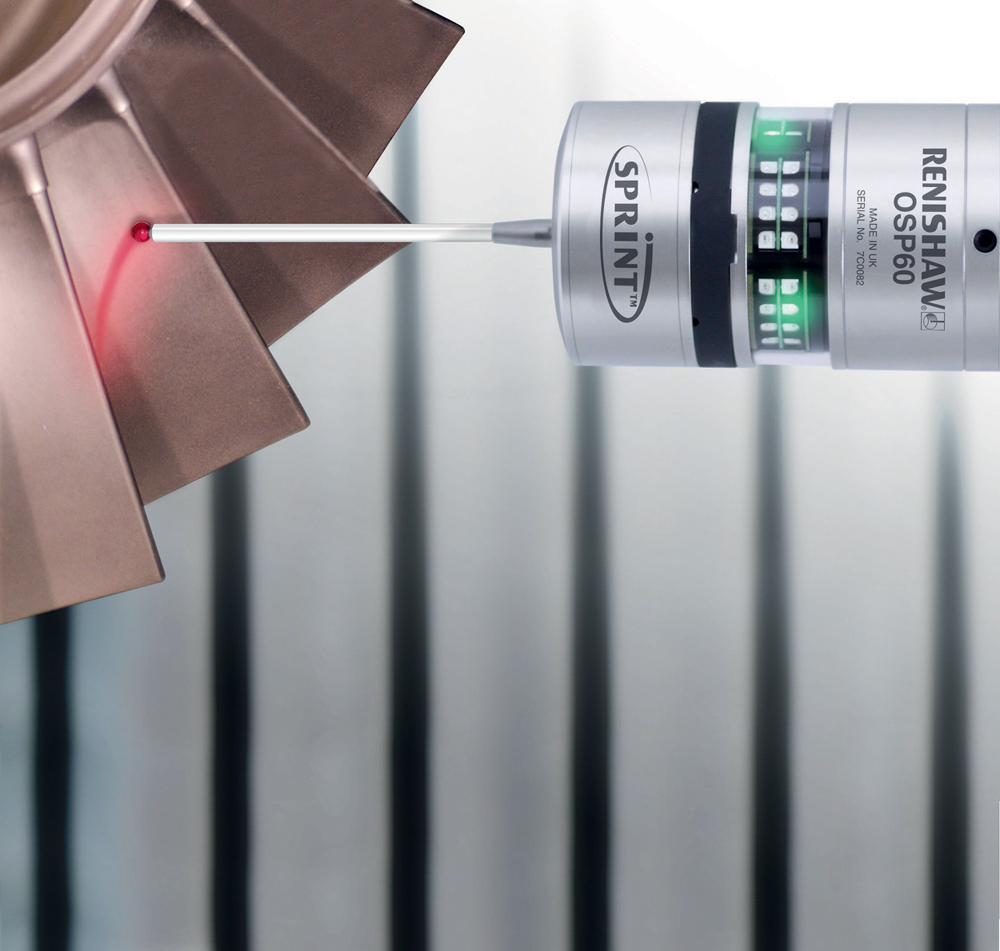

SPRINT is a game-changing system, which opens up completely new process control opportunities for high-value CNC machine tools. The SPRINT system incorporates a new generation of on-machine scanning technology that will deliver a step-change in the benefits of process control, enabling fast and accurate form and profile data capture from both prismatic and complex 3D components.

The Equator™ versatile inspection system is a radical new alternative to traditional dedicated gauging. Its patented low-cost design, unique in construction and method of operation, is capable of high-speed comparative gauging for inspection of high-volume manufactured parts. It has been developed and proven on the shop-floor in collaboration with industry-leading companies in multiple industries and applications.

Visitors to Southern Manufacturing 2014 looking to improve measurement speeds on co-ordinate measuring machines will also be able to see demonstrations of the PH20 5-axis touch-trigger system, which increases touch-trigger CMM throughput up to three times, using fast, infinite, rotary positioning and unique "head touch" capability for high-speed point capture with minimal CMM movement. The PH20 uses 2-axes of head motion to minimise CMM movement and associated dynamic errors at higher measurement speeds. Its unique "inferred calibration" feature determines head orientation and probe position in a single operation, eliminating the need for calibration at each orientation.

Renishaw’s laser melting technology will also be featured at Southern Manufacturing 2014.This additive manufacturing system is a pioneering process capable of producing fully dense metal parts direct from 3D CAD, using a high-powered fibre laser. Parts are built from a range of fine metal powders that are fully melted in a tightly controlled atmosphere, in layer thicknesses ranging from 20 to 100 microns.

CONTACT

Chris Pockett

Renishaw plc

chris.pockett@renishaw.com

www.renishaw.com

+44 (0) 1453 524524

Friday 24 January 2014 / file under Engineering | Exhibitions | Technology