Next Generation Atlas And Titan Slitter Rewinders At ICE USA 2013

Atlas Converting Equipment Ltd., in conjunction with its Charlotte, NC based subsidiary Atlas Converting North America, Inc., is pleased to confirm its participation at the ICE USA 2013

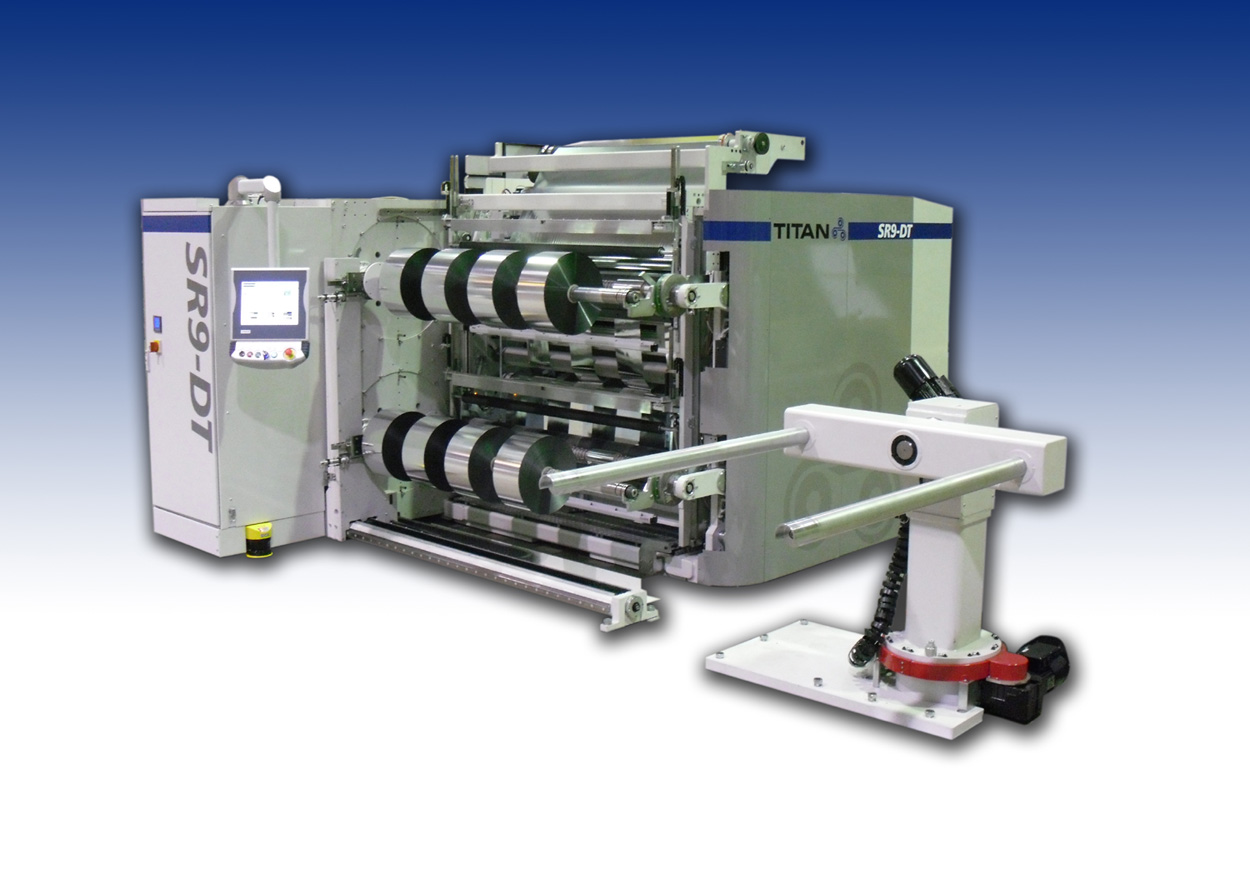

Titan SR9 Series Slitter RewinderThe exhibition in Orlando, FL is from April 9 – 11 inclusive, and Atlas can be found on Booth 857 next to the Technology Showcase Theater. The company will present its ‘next generation’ Atlas CW Series and Titan SR9 Series slitter rewinders for a wide range of plain, coated and printed film & other flexible materials in widths from 53 – 410ins. (1.35 – 10.4m).

The presence of Atlas & Titan at ICE USA 2013 will provide a convenient opportunity for the company to further promote its new Slitter Rewinder Demonstration Center in Charlotte, NC where customers are able to see demonstrations of the new Titan SR9 Series slitter rewinder and also to request performance trials using their own materials. The new Demo Center facility was inaugurated on September 21st & 22nd last year with an Open House event featuring the Titan SR9-DT Dual Turret rewinder.

TITAN

In the development of the Titan SR9 Series, Atlas focused its product development strategy on achieving significant reductions in machine downtime for printers & converters, with lower operator intervention and also reduction of costly waste materials - which all adds up to outstanding gains in productivity.

The concept of the Titan SR9 Series technology platform features three separate machine modules of unwind, slitter & rewind sections. The idea being that a converter need only change the rewind section of the machine from a Duplex Shaft (DS) to a Single Turret (ST) or Dual Turret (DT) configuration, to meet changing production requirements, without the need to change the existing unwind and slitting modules.

The Titan SR9-DT rewinder was launched at ICE Europe 2011 and the Duplex Shaft (DS) module was introduced during 2012.

Innovative engineering design has led to the application for 3 patents on the Titan SR9 Series, including the unique Turret Support Device (TSD) for faster turret rotation on the DT model which has already been granted. Such advanced engineering design has led to significant improvements in the quality of slit reels and significant reductions in set-up procedures.

A newly designed Linear Tracking Slitter (LTS) section ensures the shortest and a constant web length between the knives and the rewind shafts for improved web control giving the highest possible side wall quality of rewind reels and also reducing the possibility of waste material. Between all three versions of the Titan SR9 platform, many other new features provide exceptional performance and productivity at running speeds of up to 3,300 ft/min. (1,000 m/min). The SR9 Series is available in two widths - 65 and 88 ins (1650 and 2250 mm).

To maintain focus on its objectives for sustainability, the Titan SR9 Series has many features for achieving reductions in the cost of energy and of waste materials. Elimination of all hydraulics helps to provide a cleaner environment and the use of high efficiency motors and regenerative braking enables a considerable reduction in energy consumption and makes the SR9 Series the most efficient slitting-rewinding solution in the Titan range.

The Titan SR9 Series is set to smash all productivity records and provides a genuinely flexible and sustainable new approach to slitting and rewinding.

ATLAS

The new Atlas CW Series technology platform for primary & secondary slitter rewinders for film & flexible materials will also be presented at ICE USA 2013. The new CW technology platform introduces the next generation of more compact film slitting solutions from Atlas in web widths from 98 – 410 ins.( 2.5 to 10.4 metres) and delivers higher efficiency, increased productivity and reliability, higher quality rewind reels, reduced noise levels and more effective, operator-friendly control systems.

This latest Atlas technology also features wireless rewind arm positioning, automatic knife positioning, direct drive web path rollers and running speeds of up to 1,500 m/min. (4,920 ft/min.) with more precise web tension control. Electrical cabinets are now fully integrated in to

the machines to reduce the space required for installation with ‘under floor’ service trenches also no longer required for the primary slitter rewinders.

A new Service platform for both the Atlas & Titan range of slitter rewinders is now in place, providing expanded global customer service & support operations, with engineers not only based in Charlotte, NC but also in the UK, Mexico, India, SE Asia and China, confirming its position as a global supplier providing complete customer satisfaction.

Atlas can also provide fully automated and integrated roll handling systems to meet specific production requirements.

CONTACT

Roger Astell

Atlas Converting Equipment Ltd

roger.astell@atlasconverting.com

www.atlasconverting.com

+44 (0) 1234 852553

Saturday 9 March 2013 / file under Packaging | Converting