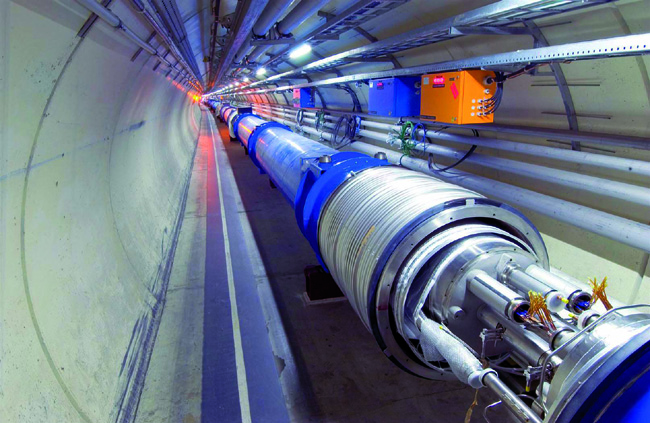

Fine Tubes In The Large Hadron Collider

It’s not often you need a product which can perform under conditions of deep outer space or temperatures close to absolute zero

Large Hadron Collider TunnelBut that’s what Fine Tubes in Plymouth have been developing with the scientists at CERN in Switzerland, for the Large Hadron Collider. The experiments there replicate conditions believed to have been at the time of the Big Bang. Fine Tubes have developed products for the cooling system to extraordinarily high specifications, virtually out of this world.

In the middle of the LHC is what is in effect the world’s largest, coldest fridge. It runs at temperatures that emulate deep outer space, close to absolute zero. The challenge CERN laid down for Plymouth-based Fine Tubes has been to make extremely precise cooling tubes for this extremely low temperature vacuum system. The tubes had to be made from a material that could handle the pressures and extreme temperatures involved, and meet a raft of extraordinarily stringent technical requirements, including very high metallurgical cleanliness, very strict leak tightness, and exceptionally low levels of inside and outside diameter halogen contamination.

After years of development, Fine Tubes have been supplying CERN with highly specialist, painstakingly developed product: – more than a hundred kilometres of unique tubes, seamless, precision-drawn in specially formulated austenitic stainless steel. The alloy maintains high mechanical strength and provides very low magnetic permeability at the exceptionally low temperatures – essential as the tubes carry a flow of supercritical helium with a temperature between 5 and 20 degrees K at a pressure of up to 2.6MPa (380 Psi).

Fine Tubes’ QA & Technical Director Dr Richard Fletcher comments: “Of course, pressures of 2.6Mpa/380psi aren’t so unusual for Fine Tubes, although some manufacturers would find it a challenge for such thin walled tubes. In fact we produce much thinner tubing – for example for aerospace customers - just 40 microns diameter, half the thickness of a human hair, which takes much higher pressures – up to 4,500psi. And of course for larger industrial applications such as oil and gas extraction or pressure vessels you may be looking at very high pressure ratings – up to 150,000 psi, 10,000bar.”

At more than 27km circumference, the Large Hadron Collider is the largest hi-tech machine in the world, yet it demands precision to microscopic levels on some of its components. For example, it has more than 1,600 superconducting magnets along its circumference. The assemblies are huge, 15m long, each weighing more than 32 tonnes. They each are positioned within an accuracy of 50 microns along the 27 km length. Fine Tubes help to cool these monsters – with delicate, high precision tubing with an outside diameter of 4.76mm and a wall thickness of 0.53mm.

The tubes form part of the beam screens, which are inserted into the beam pipes of the collider’s superconducting magnets. They had to be laser-welded onto the beam screens: this demanded exceptionally low levels of impurity inside and out, the inner walls to contain the exceptionally low temperature, and outer walls to ensure highest quality of laser welding without hot cracking.

Fine Tubes have been working on the project for years, and are delighted to see the results of the long term relationship. Brian Mercer, Sales and Marketing Director comments, “Working extensively in industry sectors such as aerospace, medical and nuclear, we’re used to developing products for the latest scientific developments. But it’s hard to be more cutting edge than in this project! It’s been the most fascinating challenge to be involved in the LHC. We started looking at CERN’s needs over 15 years ago, and developed unique tubing to extremely unusual specifications. For example, you don’t often need products to perform at temperatures of -268 degrees Celsius, approaching absolute zero. And it’s rather unusual to be working on a machine with 27km circumference yet demanding accuracy from us to 0.8 microns, that is 0.0008mm!”

Managing Director Ronen Day adds: “We’re delighted to see the results of this long term relationship, one of many across some of the most advanced organisations in science and industry. After so many years, we feel part of the team. We were delighted to hear about the breakthrough in July and joined in the celebrations with a cup of tea in Plymouth while the scientists cracked open the champagne in Switzerland. It’s good to know that the hottest news in science came out of the coldest parts in the LHD, where Fine Tube’s many miles of tubing are playing a key role.”

CONTACT

Bettina Schadow

Fine Tubes Ltd

bschadow@fine-tubes.co.uk

www.finetubes.com

+44 (0) 1752 697221

Friday 20 July 2012 / file under Technology | Engineering