New Range Of AV Mounts For Vibratory Conveyors

Anti-Vibration Methods (Rubber) Co Ltd (AVMR) have developed a range of special AV Mounts to suit vibratory conveyors

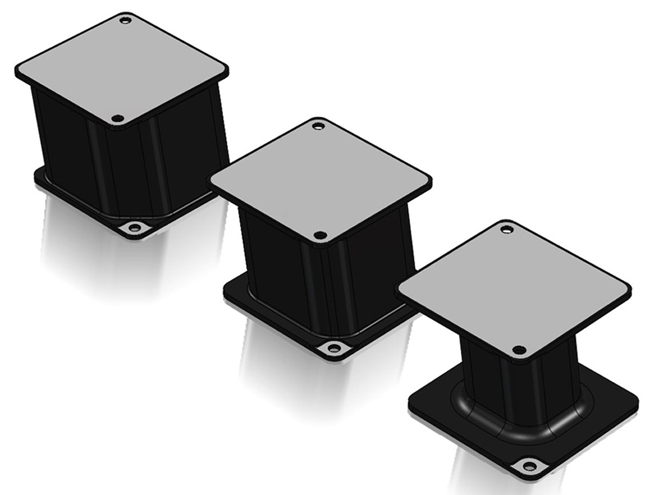

AV Mounts To Suit Vibratory ConveyorsIn such applications and for optimum isolation, a high degree of static deflection is required. In this new design, the mount has parallel mounting faces but these are offset by 15mm to provide a greater potential for deflection.

The SW-R series is based on a range of material hardnesses and cross-sections to achieve a family of AV mountings.

This new range of high deflection anti-vibration sandwich mountings covers a standard compressive load range between 50 and 1200Kg per mount. Optimum deflection is 15mm thus providing very high levels of isolation (97% @1500rpm or equivalent forcing frequency). The mountings can be used as conventional compression mounts or as shear mounts when reduced loading is required.

The different designations R1 to R7 are created by using different cross sections (68, 98 or 112mm x 95mm common height) and also different material hardnesses.

The standard materials used are 316 stainless steel for the mounting plates and natural rubber materials. However, any from the company’s wide range of natural, neoprene, nitrile or EPDM materials can be manufactured

The company specialises in the creation of solutions for both vibration and shock isolation across a broad range of industries. Current applications for this unique mounting are primarily in the food processing and material handling fields.

Bonding or rubber materials, particularly to metallic substrates remains a speciality of AVMR The specialisation for providing isolation solutions utilising a wide range of materials and techniques remains a core strength of the business for its vibration and shock mitigation sector.

CONTACT

Peter Dunn

Anti-Vibration Methods (Rubber) Co Ltd

peter@antivibrationmethods.co.uk

www.antivibrationmethods.com

+44(0) 1985 219032

Thursday 19 April 2012 / file under New Products | Machinery | Engineering