Refurbishment Of Track Pads

For many years Anti-Vibration Methods (Rubber) Co Ltd - AVMR have manufactured track pads for a variety of applications

Anti-Vibration Track PadsFrom this experience, the company has recently secured an order to re-furbish 400 track pads not originally manufactured by AVMR.

Many of the projects in recent years have been related to the track mounted pads utilised for feeding undersea cables from support vessels. Such installations could cover up to 2000km in a single cable laying operation.

Although many new installations are for fibre optic cables, the final size of the cable including multiple layers of physical protection and shielding layers can be much larger (160mm) than the few mm required for the fibre optic element. Power cables can be significantly larger – typically 300mm diameter.

In deep sea installations where the weight of the cable would free-fall to the ocean bottom, it is necessary to provide a tensioning mechanism. AVMR has provided pads for such applications which are mounted between pairs of tracks which grip the cable to control the rate of descent.

In these applications the pads are chemically bonded to a steel backing plate which has holes or studs to allow fitting to a standard track hole pattern,

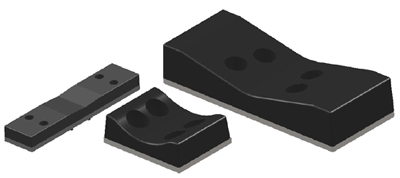

The largest of the pads above is approx 450mm long.

One project required a dual purpose track pad to support both 129 and 157mm diameter cables in a single design. The design work was carried out by AVMR and has proven very successful in operation.

To complement the manufacture of track pads, AVMR have recently undertaken the refurbishment of 400 pads as pictured in various stages from as received to the final remoulded track pad. These pads have an aluminium backing plate which is very badly corroded by contact with sea water, but it is still more economic to refurbish these than to manufacture from new, with new castings.

The process employed by AVMR includes the cryogenic treatment of the pads to remove 99% of the rubber from the surface. This is followed by an aggressive grit blasting process to remove surface corrosion and other traces of old rubber.

Prior to re-moulding, the pads are subjected to hot vapour degreasing and then the chemical bonding agents are applied by spray.

The actual rubber bonding/moulding is carried out in a 4 cavity mould tool. The rubber used in this instance is from our range of military materials (MVEE specs.)

AVMR will be happy to quote for new production or refurbishment of existing products of a similar type and can design mould tooling in-house for such products up to 600mm long. Materials used can be any from our extensive existing range which includes natural rubbers between 35 and 90ShA, or from a range of Neoprene, Nitrile or EPDM materials.

Bonding or rubber materials, particularly to metallic substrates remains a speciality of AVMR The specialisation for providing isolation solutions utilising a wide range of materials and techniques remains a core strength of the business for its vibration and shock mitigation sector.

CONTACT

Peter Dunn

Anti-Vibration Methods (Rubber) Co Ltd

peter@antivibrationmethods.co.uk

www.antivibrationmethods.com

+44(0)1985 219032

Friday 30 March 2012 / file under Utilities | Machinery | Engineering