Large Thorax Radiotherapy Shells

Ridat Company, London based manufacturer of thermoforming machinery, in partnership with RCS Thermoforming Company, has launched a new vacuum forming machine to produce large Beam directional shells

One such machine has recently been installed at City Hospital, Nottingham.

Kevin Evans, Head of Clinical Radiotherapy Technology, said that he opted for the vacuum forming process in preference to the currently more common thermoplastic route because the vacuum formed shells are more accurate, better in replicating the contours of the body, less flimsy, can be readily labelled and much more suitable for skin sparing.

Presently, these transparent plastic shells are used to immobilise and position the patients comfortably so that the external beam radiotherapy can be planned and given in a precise and repeatable manner. Use until now has been mostly limited to the head and neck.

The larger Thorax shell extends from the cheek to the diaphragm, could be made on the model 3624 Medivac and used for patients requiring treatment of the oesophagus.

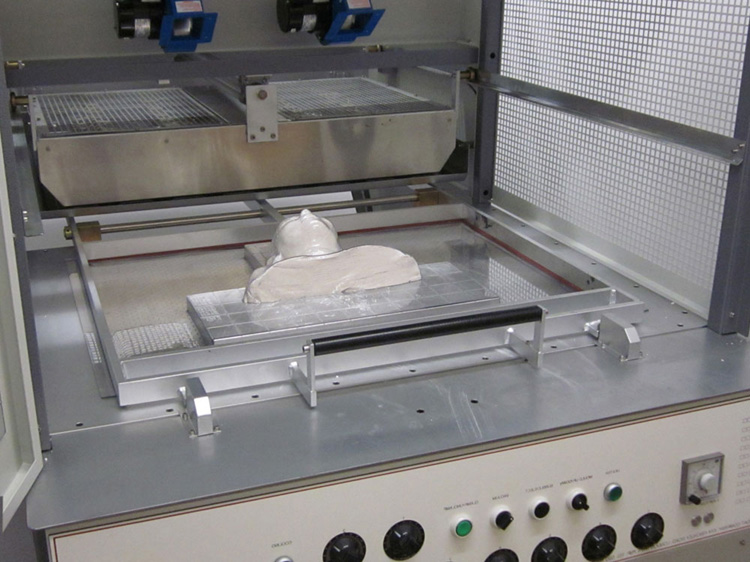

The Ridat model 3624 Medivac has a forming area of 36” by 24” (914mm x 610mm) and is also fitted with a reducing aperture for the smaller moulds.

To make the shells, an impression of the patient is first taken and from this a plaster positive cast is made.

The cast is placed in the Ridat machine and plastic film is heated and down over the cast by applying vacuum. This process was originally developed in conjunction with Royal Marsden Hospital in the early 70’s.

CONTACT

Dipak Sen Gupta

Ridat Company

info@ridat.com

www.ridat.com

+44 (0) 20 8458 6485

Thursday 18 August 2011 / file under Healthcare | Medical | New Products