Hughes Safety Protecting Workers with Safety Showers in the Gigafactory Boom

Work is already well underway in preparation for the phase-out of petrol vehicles across Europe

The UK Government announced a ban on the sales of new internal combustion engine (ICE) cars and vans - though the original date for this has been pushed back from 2030 to 2035.

Last March (2023), the European Parliament voted to approve new legislation to ban the sale of petrol and diesel cars from 2035. And although it will need to go to the European Council before being made official, the transition to all-electric vehicles is gaining speed.

In 2028, the unit sales of new electric vehicles in Europe are expected to reach 3.44 million, with a further 1.4 million unit sales of new plug-in electric hybrid vehicles¹. And where there's a demand for electric vehicles, a demand for lithium-ion batteries follows.

Currently, there is just one UK gigafactory - AESC UK in Sunderland, which supplies batteries for Nissan's electric vehicles. As in countries across Europe however, this figure is expected to rise in the coming years - with Germany, Hungary and France expected to become home to 19 of them².

Due to the nature of the hazards involved in the production, battery gigafactories are considered to be high-risk environments. But why?

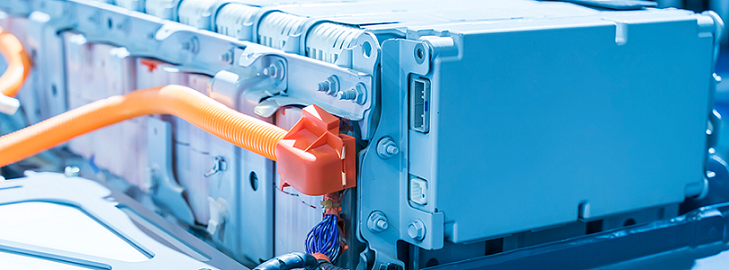

The science behind lithium-ion car batteries

Lithium-ion batteries are formed of four main components.

• The capacity of the battery is determined by the cathode - it's the source of the lithium ions.

• The ions are stored in the anode, which enables the electric current to flow through an external circuit when the battery is charged.

• The separator is the physical barrier that keeps the cathode and anode apart.

• The electrolyte acts as a conduit of lithium ions between the cathode and anode.

Before a battery can be installed, the factory must charge and test the unit to identify any faults. It can become faulty when mishandled, overcharged, short-circuited or heated up - leading to issues such as the battery walls expanding or splintering, which can allow some of the internal compounds to leak out.

Electrolytes are made up of organic compounds, such as salts and solvents. When contained inside a battery unit, the electrolyte doesn't pose an immediate risk. If they spill from a battery, because of an accident or if they're handled improperly, they can react with air and water to produce hydrofluoric acid - which poses a significant risk.

What are the effects of a hydrofluoric acid burn?

He said: “Hydrofluoric acid is one of the strongest acids that causes corrosive burns and can also involve underlying bone. It is highly toxic and damaging. Contact with high-concentration products can be fatal.”

When a person first comes into contact with hydrofluoric acid, they’ll experience severe pain at the site of the burn. Kanani elaborated stating: “There may be swelling, slow-healing burns, blisters or a rash present and pain can occur even if there are no visible burns.”

The lasting damage can be significant too, with Kanani adding: “Skin damage can take a long time to heal and can result in severe scarring. Eye exposure can cause permanent blindness or total destruction of the eye.”

Safety showers: providing front line protection in gigafactories

Battery gigafactories are extremely complex facilities, with a variety of different conditions. From manufacturing areas featuring extremely high temperatures and little to no humidity for the drying process, to clean rooms with high filtration levels to reduce the presence of dust particles.

Naturally, PPE is absolutely imperative, including head, face, respiratory and hand protection. However, emergency procedures must be in place if there is an accidental leak. This is where safety showers and eye/face washes play such an important part in keeping workers safe. They offer an immediate line of defence against the dangers of hazards, like hydrofluoric acid in the gigafactory environment.

To thoroughly decontaminate in the event of corrosive spills, EN15154 regulations state those affected should flush the skin or eyes for at least fifteen minutes. The water delivered should be tepid (between 15°C and 37°C), and comply with a designated flow rate (depending on its class).

By flushing away chemical contaminants and minimising the effects caused by chemical exposure, safety showers have a vital part to play in the lithium-ion car battery boom.

CONTACT

Wendy Baker

Hughes Safety Showers Ltd

sales@hughes-safety.com

www.hughes-safety.com

+44 161 430 6618

Monday 11 March 2024 / file under Automotive | Engineering | Safety