Three High Sensitivity Metal Detectors For Nappies

An Egyptian paper mill has purchased three meTRON 07 CI Metal Detectors mounted on conveyors to detect metal in the tissue paper used as the filler in the manufacture of baby’s disposable nappies

Bunting is one of the world’s leading designers and manufacturers of magnetic separators, metal detectors, magnets, magnetic assemblies and magnetising equipment. The Bunting European manufacturing facilities are in Redditch, just outside Birmingham, and Berkhamsted, both in the United Kingdom.

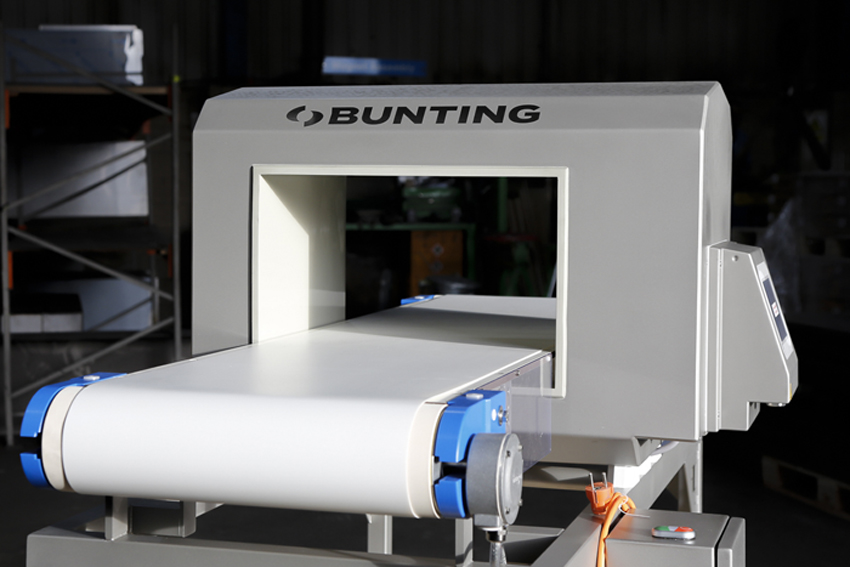

The three meTRON Metal Detectors are identical in size and specification. Each has a 400mm wide belt passing through a 450mm wide by 300mm high opening. The Metal Detectors are designed to detect a wide range of metal contamination. The high sensitivity enables the identification of ferrous metal (1.75-2.0mm), non-ferrous metal (2.0-2.5mm) and stainless-steel (2.5-3.0mm).

The meTRON Metal Detectors are a closed funnel design built in 304 stainless steel with an IP66 ingress protection rating. To ensure maximum detection performance at all times, the coils are auto-balancing. Access to the settings is via a 5.7” VGA colour touch display which features a three-level password.

The conveyors supplied with the Metal Detectors are designed to transport boxes containing the product through the detection area. Each is 1700mm long with three different hights of 950mm, 1050mm and 1150mm. The conveyor control panel has a start-stop switch and emergency stop button. The nominal belt speed is 0.6 m/s and the inclusion of a frequency inverter allows this to vary between +/- 40%.

Passing through the Metal Detectors are 10kg bags 558mm long, 355mm wide and 200mm high. The customer plans to pass approximately 40 packs per minute through each Metal Detector.

“This is a high-profile project which needed careful consideration to ensure we proposed the best metal detection solution,” explained Simon Ayling, Bunting’s European Managing Director. “The client wanted a Metal Detector that was simple to operate, but could detect the smallest metal. We supply many meTRON 07 Metal Detectors and this design was perfectly suited for this application.”

CONTACT

Simon Ayling

Bunting - Berkhamsted

sales@buntingeurope.com

www.buntingeurope.com

+44 1442 875081

Tuesday 3 March 2020 / file under Engineering | Machinery | Metals | Safety | Textiles