Tackling Drying Challenges Faced By The Cable and Wire Industries

Driving productivity in wire and cable products requires consideration of best practise in process drying

As an innovative provider of blower-driven equipment for industrial surface drying applications, ACI is assisting some of the World’s leading cable and wire manufacturers and earning a solid reputation for producing quality, engineered drying process units.

Because of recent legislative efforts, solvent based inks and coatings have virtually disappeared within the cable and wire industries. This has meant manufacturers focussing on producing products that are both cleaner and dryer than ever before, in order to allow water based inks and coatings to adhere correctly.

Compressed air systems used in older Wire and Cable manufacturing plants were installed when utility costs were low and the cost of energy consumption wasn't monitored as it is today with regards to increasing the bottom line. Now PLC's monitor every aspect of modern Wire and Cable lines, helping to identify the source of downtime and production slowdowns. When printing, inspection, testing or packaging adversely affects the manufacturing process, ACI Cable and Wire Drying Systems can be counted on to eliminate all moisture.

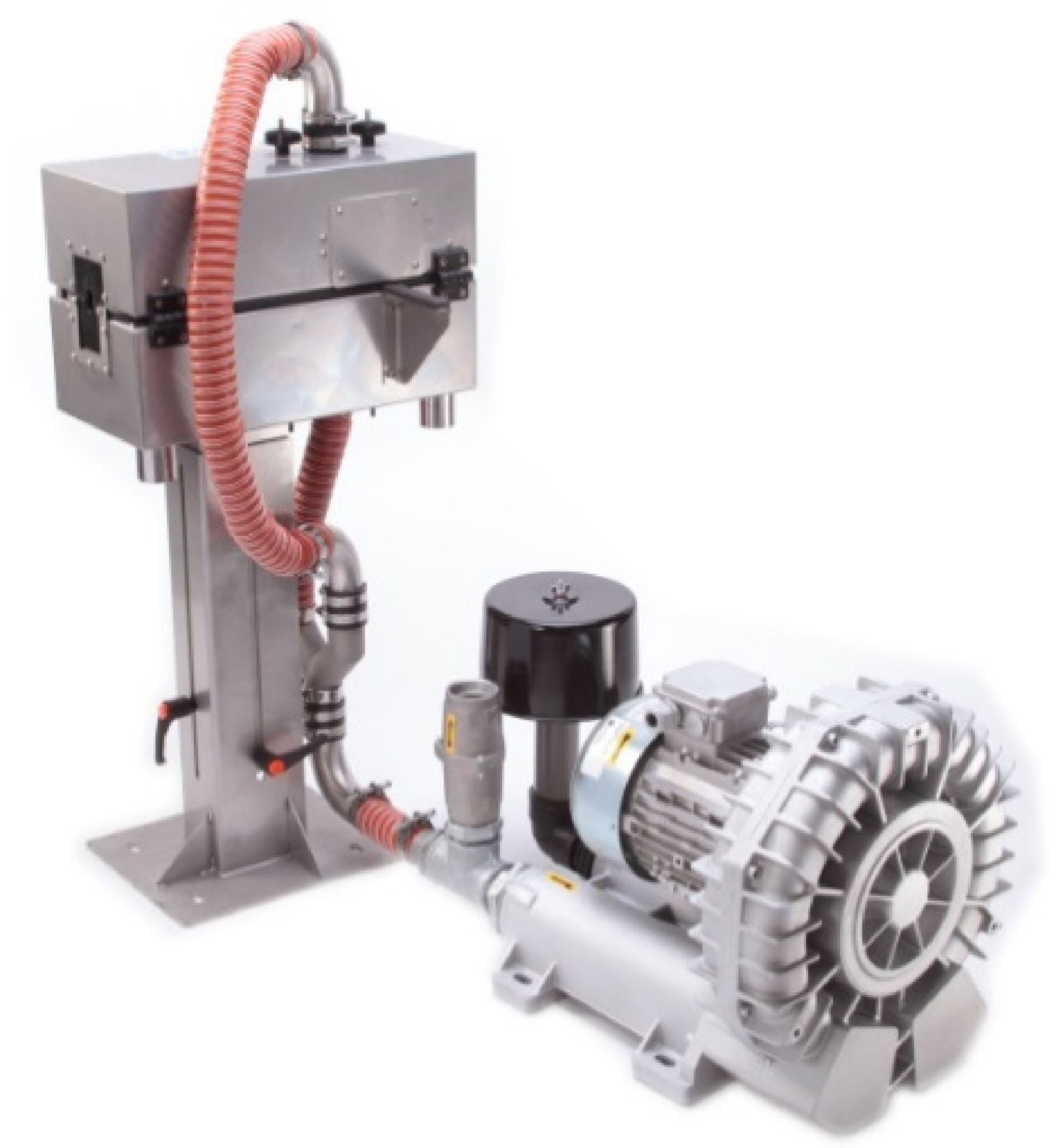

The ACI LINE-Dry System is a self-contained, blower-driven drying unit that uses precisely controlled air flow to dry tube, cable, wire and extrusion products. They work by closely focusing powerful angled air jets against the flow of the product. These air jets are typically opposing, and aim at the top and bottom of the product to hold back the advancing residual moisture. This is achieved by breaking the surface tension of the water, allowing it to gather and puddle before from the jets.

“The implementation of these new drying units into our current lines is seen as significant. ACI solutions lead to huge improvements and developments in health & safety, environment, costing, maintenance hours, prevention of corrosion to equipment and measures of quality control” states Sam Donnelly, Project Engineer for Prysmian Cables.

Sam continues, “The long-term advantages of having the ACI LINE-Dry System in place outweighs any hesitations about purchasing the system. It proved its ability to meet all our needs, as shown by the fact we have installed two further units. It dries cables up to 35mm efficiently at speeds up to 400m/min and has eliminated all the problems associated with water carry-over helping to reduce running and maintenance costs.”

CONTACT

Mathew Forknall

Air Control Industries Ltd

sales@aircontrolindustries.com

www.aircontrolindustries.com

+44 1297 529242

Wednesday 6 June 2018 / file under Engineering | Packaging | Power | Utilities