WEBTEC Helps Find A Portable Monitoring And Data Capture Solution

AMC Jets has over 20 years experience in servicing companies using high pressure water jet cutting technologies worldwide

A potential and widespread issue in their field of operations is a reduction in hydraulic system pressure, which often leads to performance decay of the water pressure intensifier.

AMC Jets went to WEBTEC to find a portable monitoring and data capture solution that was outside Webtec’s current experience. Even though they had never investigated pressure sensing of this magnitude before, (5000bar), they could see no reason why it couldn’t be incorporated into the Webtec data logging equipment.

Predictive maintenance

Simply put, prevention is better than cure. The concept of predictive maintenance means the testing of a system that is working, in order to predict when it may start to fail, thus enabling maintenance and repair before any catatrophic failure. It allows planned sourcing of expensive parts before they are needed and a significant reduction in downtime since parts are available on standby as they are required. It also means that panic jobs are minimised and so the quality of any maintenance or repair is never compromised. It can save time and money and the associated lack of unplanned downtime is of huge value.

The AMC Jets project – high pressure hydraulics

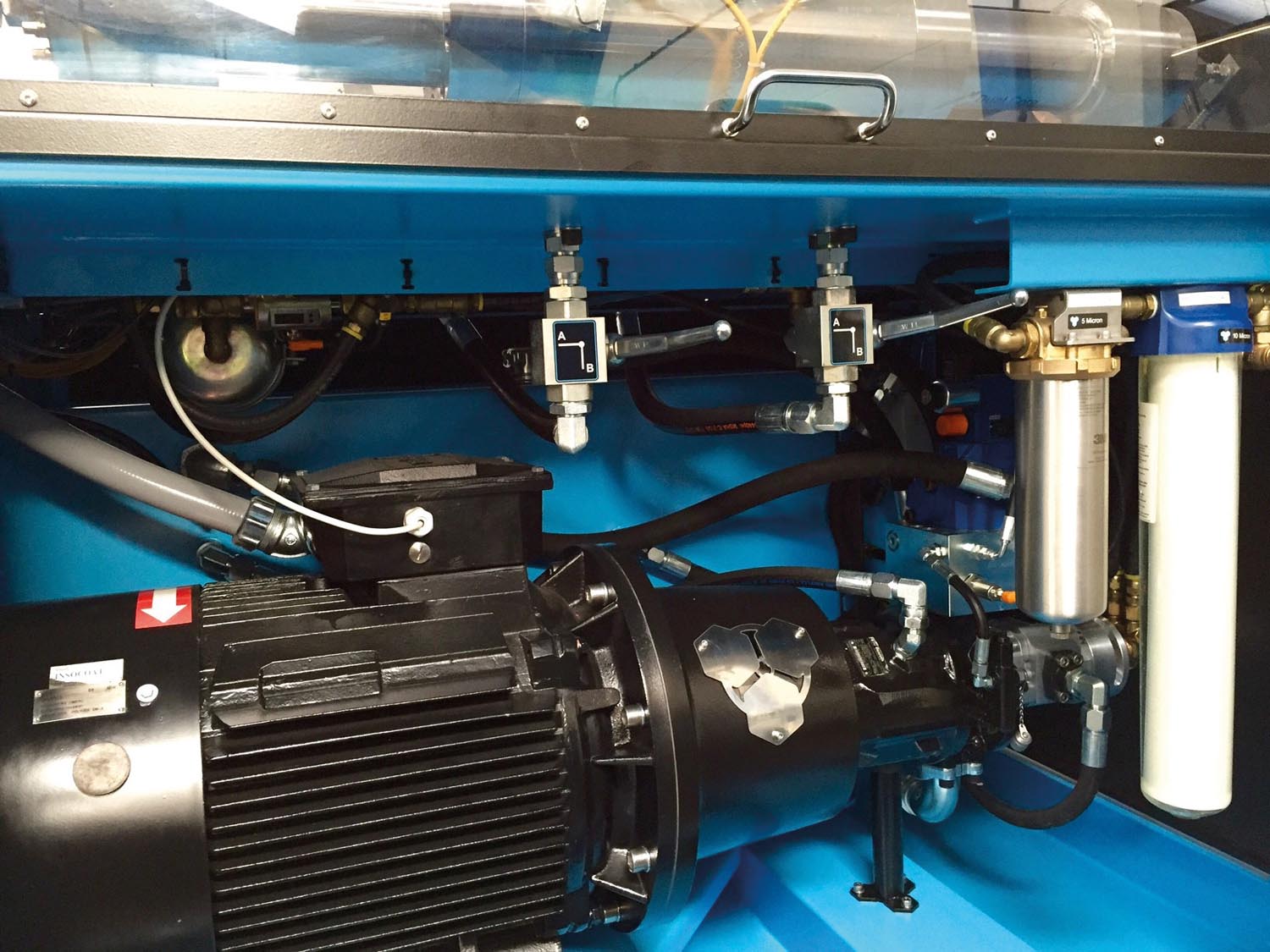

Hydraulic pressure measurement alone is insufficient - the behaviour of the hydraulic system generating the pressure is also important in determining the likelihood of failure. Therefore, AMC Jets wanted to measure flows, pressures and temperatures on the power supply hydraulic system, and also simultaneously measure the intensified water system pressure. They also recognise that contamination is the source of 80% of hydraulic failures, so they also needed to constantly assess the condition of the hydraulic oil.

Since they were already using an MP Filtri in-line condition monitor, AMC Jets specified this unit as a core requirement, as well as a very high water pressure sensor, which they sourced and supplied themselves. This was an ideal opportunity for Webtec to engineer a solution for the client that would ultimately be useful for other clients in other areas of operations. AMC Jets also wanted a portable data logger that would be easy to install and use, and discussed several Webtec alternatives of flow and pressure sensors, combined with a Webtec hydraulic data logger, the HPM6000 series.

The solution – bespoke and portable

Within their quotation, Webtec clients are provided with embedded hyperlinks to technical datasheets, providing all the information they need to discuss how best to customise their kit precisely, rather than having extraneous and unused cables and sensors.

The final engineered solution for AMC Jets system consists of a portable data logger, four flow meters with on-board temperature, four pressure transducers, a particle counter and all relevant connectors and cables.

An important part of the brief for this client was portability. Due to the size and bulk of the system it is not practical for it to be contained within one carry case, and therefore was split into two separate cases, the idea being to have a wet and dry cases as necessary. Webtec specified these with wheels for easier portability and commuting. Since delivery the client has decided to add a third, to contain all of the flow meters permanently mounted on a single panel, ready to connect on site. The case was also configured with space for a 25lpm stainless steel positive displacement flow meter for monitoring the water hydraulics at a later date.

The system itself took around six weeks to implement following some upfront feasibility engineering. The client also required the inclusion of an on-site training session as part of the project, and Webtec were given the projected test regime to use as an integral part of that training. The data collected was examined to ensure it met with AMC Jets objectives, enabling collaborative test process adjustments along the way.

Feedback

While the system is recent, initial feedback from the client has been very positive. Aside from their own satisfaction, they are happily passing on recommendations to their own customers. They believe the data analysis service will be a chargeable service for their own customers, partially refundable on acceptance of service recommendations.

The HPM6000 hand held portable data logger unit comes complete with HPMcomm™ software which enables them to download and save test data, archiving it to their computer. This benchmark or reference can be repeated months or years later and analysed by overlaying the old and new data, so comparing performance of the same serial number machine over time and gradually identifying its performance decay. Visually and graphically, AMC can point to their customer’s failing components.

Conclusion

AMC Jets are interested in coordinating a visit to their largest customer, taking their system with them. A similar system on-site would be ideal, and AMC Jets can then provide the necessary expertise to their larger customers if they purchase their own systems. They are being very forward thinking in the service they offer to their customers to reduce downtime.

The principle is equally applicable to hundreds of different types of hydraulic equipment in industry, not only water jet cutting machines.

Maintenance only when needed and servicing only components that need to be serviced is as important as reducing unplanned downtime for maintenance. The business advantages are huge.

CONTACT

Martin Cuthbert

Webtec Ltd

sales-uk@webtec.com

www.webtec.com

+44 1480 397400

Monday 2 April 2018 / file under Aerospace | Engineering | Marine