Renishaw Will Attend The American Academy Of Orthopaedic Surgeons Annual Meeting 2018

Global engineering and healthcare technologies company, Renishaw, is attending the American Academy of Orthopaedic Surgeons (AAOS) Annual Meeting in New Orleans, Louisiana

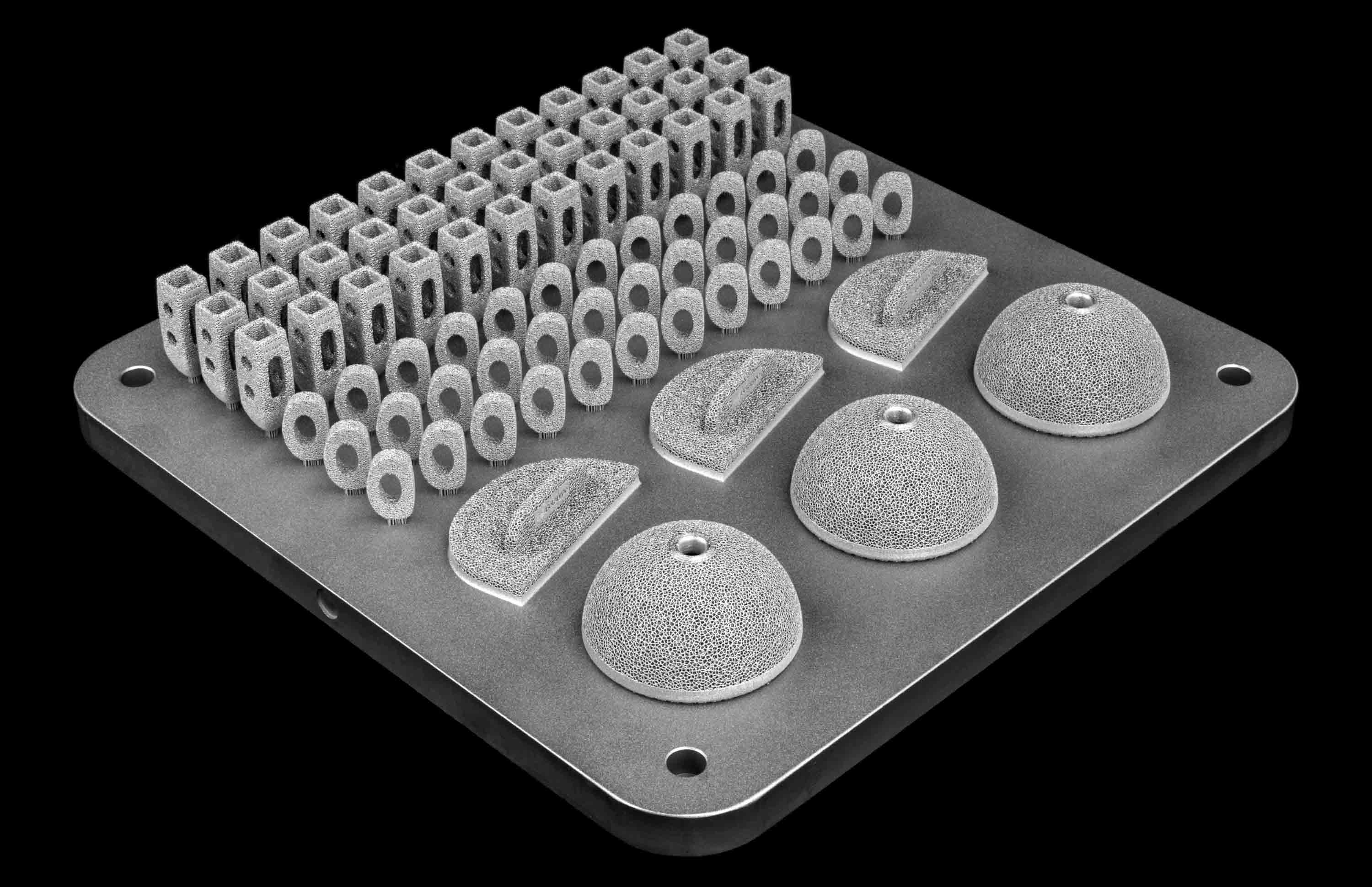

Renishaw will be exhibiting a range of prototype orthopaedic implants additively manufactured (3D printed) in titanium on Renishaw’s healthcare-optimized additive manufacturing (AM) systems.

Dr. Jonathan Jeffers of Imperial College London, UK, will present data from an ongoing project, funded by the UK government and Renishaw, investigating the development of load bearing lattice structures for orthopaedic implants. By incorporating a lattice, implants can provide a scaffold structure for new bone tissue to grow into. The spacing and strut thickness of the lattice can be optimized to match the stiffness of surrounding bone. It may be possible to create a strain gradient on the bone which can accelerate growth.

“The partnership between Imperial College London and Renishaw is creating really exciting data on new materials that can control the way bone repairs itself. These materials could change the way orthopaedic implants are designed in the future, and certainly provide an opportunity to improve patient outcomes by repairing the musculoskeletal system with materials that can invoke a desired response in bone”, commented Dr. Jonathan Jeffers.

Betatype is a London based company and a technical collaborator in the research project, providing its expertise in design, engineering and material science. Betatype’s deep understanding of manufacturing technologies helps to optimise the complexity in part production to deliver the optimum balance in terms of features, quality and production speed for AM applications. Ahead of the AAOS Meeting, Betatype founder Sarat Babu commented: “On display at the show will be a portfolio of additive manufacturing builds to showcase what can be achieved on the Renishaw platform with Betatype capability. The builds include lattice structures which are more complex, in terms of resolution and density, than anything that can usually be achieved using traditional manufacturing techniques.”

Renishaw’s additive manufacturing systems produce implants using a process known as laser powder bed fusion (LPBF). During the process, lasers are used to melt metal powder in layers as thin as 30 microns. As the powder melts a solid product is formed. This method allows complex, customized designs to be manufactured quickly and with little waste.

The AAOS Annual Meeting brings together experts in the fields of orthopaedic surgery, research and technology. The event will take place at the Morial Convention Centre in New Orleans, Louisiana, March 6-7.

CONTACT

Chris Pockett

Renishaw plc

uk@renishaw.com

www.renishaw.com

+44 1453 524524

Friday 9 March 2018 / file under Engineering | Medical | Technology