Quality Control Of Alcoholic Beverages Relies On OEM Pumps From Watson Marlow

Zeutec Opto-Elektronik of Rendsburg, Germany has adopted 114 series OEM peristaltic pumps from Watson-Marlow Fluid Technology Group

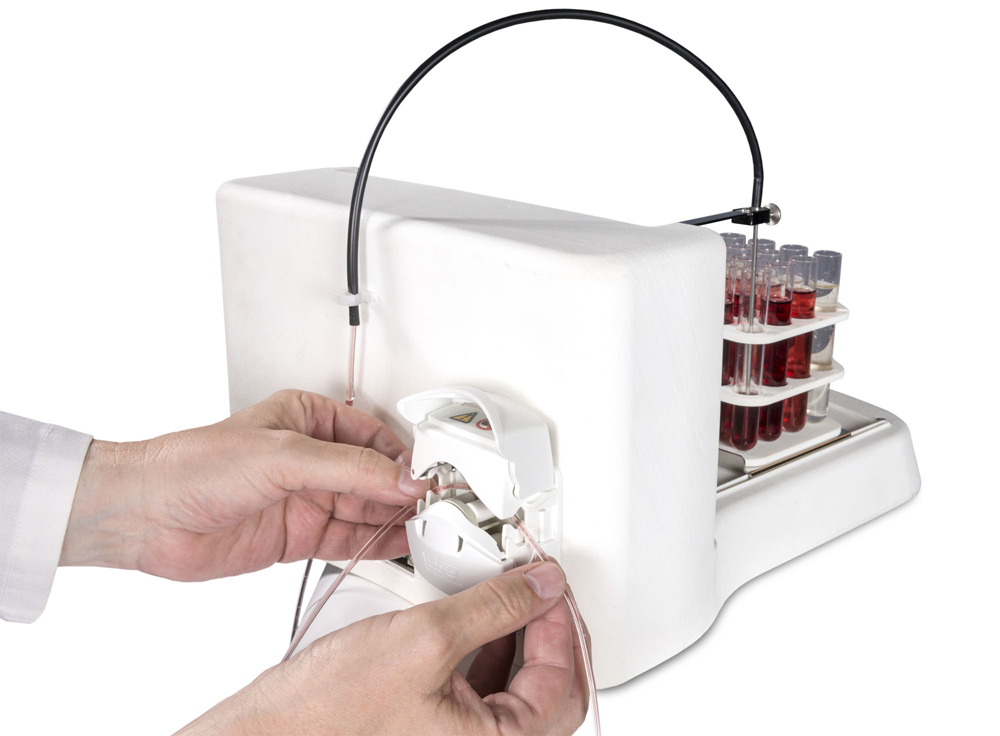

With technology that partners the company’s latest SpectraAlyzer 2.0, a near-infrared (NIR) analyser for alcoholic beverages such as wine, beer and spirits. Zeutec, which is a leading supplier of spectrometer systems, now relies on the peristaltic pumps for use in an auto-sampler, which is used to prepare samples ready for analysis by the SpectraAlyzer.

Fast and easy operation

The Zeutec SpectraAlyzer is able to indicate the most important parameters relating to the quality of alcoholic beverages in a matter of moments. In the case of wine, for example, such parameters will include alcohol, sugar and acid content as well as pH value, density and colour.

The main advantage is that NIR methods can be carried out quickly and cost-effectively during the production process. For this reason, the SpectraAlyzer is already proving popular with large alcoholic beverage producers, such as Moët & Chandon and Pernod Ricard. For larger producers, it is particularly important to be able to carry out automated measurements because it can take a great deal of time to feed in and present samples manually. This is why Zeutec has developed its own compact XY auto-sampler which can take up to 32 samples automatically.

“Around 60 measurements per hour are no problem when using the auto-sampler,” explains Daniel Hembd, Head of Research and Development at Zeutec. “The sample liquid is taken with a filling needle. Then, the peristaltic pump fitted to the back of the auto-sampler conveys the sample to the measuring cell, and then into a container.”

Prioritising versatility

When designing the auto-sampler, it was particularly important to be able to offer the end user as much flexibility as possible. This is why Zeutec relies on versatile 114 series OEM pumps from Watson-Marlow.

“We tested pumps from several manufacturers, but most were limited in terms of possible applications,” says Mr Hembd. “For instance, they would usually only take a specific type of tube, but our customers often experiment with various tube materials and sizes. What’s more, most of the pumps we tried were too complicated to operate, particularly when it came to changing the tube. The pump is located at the back of the auto-sampler, so it is important to us that the tube can be changed easily.”

The 114 series OEM peristaltic pump from Watson-Marlow is suitable for a number of different tubes with an internal diameter ranging from 0.5 to 4.8 mm. In addition, the compact and virtually maintenance-free pumphead facilitates a precise and reproducible flow rate ranging from 2 µl/min to 510 ml/min. Thanks to an innovative flip-top lid, the tube can be replaced in a matter of seconds in only a few steps and without tools.

Low pulsation

As well as being easy to use, another impressive feature of the pumphead is its very low pulsation, which comes courtesy of four rollers. For this reason, the 114 series OEM pump is often favoured for use in analytical applications. Indeed, another important argument for the pump was its suitability for continuous tubes.

“In the case of a continuous tube, there are no points between the auto-sampler and the measuring device where deposits can build up or where air can get into the sample and have a negative impact on precision,” explains Mr Hembd.

Continuous tubes not only exclude the risk of cross-contamination, they also reduce the cost of replacing tubes. When the tube becomes worn at the point where it is squeezed, it can simply be moved on a few centimetres.

Satisfied customer

Zeutec is so satisfied with its OEM pumps from Watson-Marlow that the company is now offering the pump and its simple operation to customers that operate the SpectraAlyzer without the auto-sampler.

“We have decided to offer the Watson-Marlow pump as a reasonably priced cased pump to customers who only perform occasional measurements,” confirms Mr Hembd.

CONTACT

Mike Sullivan

Watson-Marlow Fluid Technology Group

mike.sullivan@wmpg.com

www.wmpg.co.uk

+44 (0) 1326 370370

Wednesday 8 April 2015 / file under Technology | Food and Beverage