Demon Of A Process In Seaford

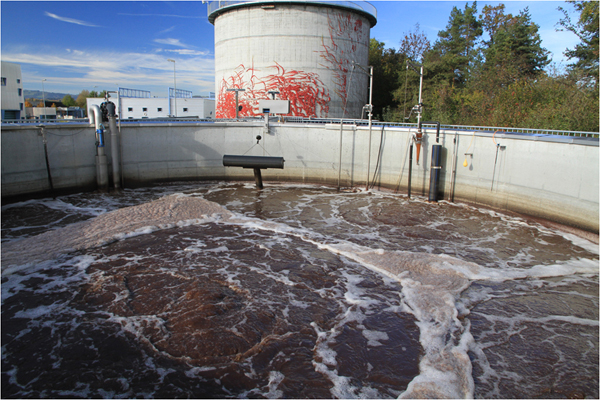

A submersible Landia mixer is helping World Water Works Inc. (WWW) at North America’s first operating implementation of the ground-breaking DEMON sidestream deammonification process

The process removes nitrogen from wastewaters containing high ammonia concentrations (>200 mg/L).

Designed to agitate, homogenize and suspend solids in

demanding conditions, Landia’s submersible mixer model POP-I is utilized to mix granulated sludge for World Water Works’ DEMON process at York River Treatment Plant in Seaford on Virginia’s coastline.

Oklahoma-based World Water Works teamed up with regional wastewater treatment utility HRSD in a private-public partnership to successfully install the centrifuge centrate treatment process - used previously only in Europe.

Deammonification, which is partial nitritation by ammonia oxidizing bacteria (AOB) combined with anaerobic ammonium oxidation (anammox), provides up to 70-90 percent total nitrogen removal. It also sees a 50 percent reduction in alkalinity requirements (compared to traditional nitrification-denitrification), a 65 percent reduction in aeration energy, and a 100 percent reduction in supplemental carbon. Unlike conventional and typically costly nitrification denitrification methods for removing nitrogen, which require large amounts of energy and methanol, the DEMON process’ AOB and anammox efficiently and effectively remove ammonia from wastewater. This anammox-based deammonification system uses 60 percent less energy and completely eliminates the need for methanol. It also produces 90 percent less sludge than conventional systems. As well as reducing costs, the anammox based DEMON process features a low carbon footprint because it sequesters carbon dioxide.

The DEMON (an acronym for DEamMONnification) process, provides great system resilience and lessens the need for oversight and maintenance. It is one of several available forms of single-step (in the same tank) partial nitritation-anammox designed for centrate treatment from anaerobically digested Biosolids and operated as a sequencing batch

reactor (SBR).

Featuring a propeller that is shaped for optimum flow/homogenization, Landia’s POP-I mixes the anammox biomass in a versatile on/off operation, kicking in automatically for the non-aeration cycle.

Speaking for World Water Works, Daniel Dair commented: “High concentrations of ammonia in effluent present a continuing problem for municipal wastewater plants and many industrial facilities. As part of the solution we provide, Landia’s mixer is very adaptable, as well as proving highly effective and extremely reliable for the DEMON process. We also get good support from Landia”.

Soren Rasmussen, Director, Landia Inc, added: “We handle a wide range of mixing applications, ranging from thin liquids to very heavy sludge, and everything in between. The DEMON process is one of several interesting technologies that World Water Works offers. We also supply low-speed mixers for their Moving Bed Biofilm Reactors, where we agitate the plastic biofilm carriers in Anoxic MBBR tanks. It’s these types of unique mixing applications that make it fun to be a mechanical engineer in the wastewater industry, plus WWW is a very enjoyable company to work with”.

While this process had been applied at around 40 plants in Europe, it had not been implemented elsewhere in a full-scale application. This was primarily because of the requirements for seeding the process using imported biomass from European operating facilities.

Originally developed and patented by the University of Innsbruck in Austria, the DEMON process is installed in over 40 systems. Due to the large energy and carbon savings, there is significant interest in this product worldwide.

HRSD’s York River Treatment Plant, located in Seaford, Virginia, currently includes a fully aerobic nitrifying activated sludge system with post denitrification filters. The plant was also the site of another first that made it a stellar candidate for the DEMON® process.

In 2002, HRSD launched Virginia’s first municipal water reuse project at Seaford, which required the construction of an SBR. However, the initiative ended when an adjacent refinery, the only reclaimed water customer, closed. Consequently, during recent plant upgrades, the SBR and equalization tanks installed to support the reuse project were retrofitted to serve for centrate equalization and full nitrification. This meant that only minor piping needed to be carried out to install DEMON®, making the project far more affordable and sustainable.

The DEMON process was seeded with 5,000 gallons of concentrated anammox biomass by mixing the imported anammox biomass with plant effluent. After some minor modifications to the equalization tank, the process soon achieved operating objectives for ammonia loading and total nitrogen removal.

Serving 17 localities in south-eastern Virginia, HRSD (Hampton Roads Sanitation District), was created by public referendum in 1940 to eliminate sewage pollution in the tidal waters of Chesapeake Bay.

HRSD owes its creation to oysters, a very robust seafood industry in the early 1900s. The Virginia Department of Health condemned a large oyster producing area in 1925, bringing the question of sewage pollution firmly into the spotlight.

As the region has grown and its needs expanded, HRSD has remained dedicated to protecting and enhancing the environment where it has an enviable record in the wastewater industry. Residents of its communities in Virginia are able to fully enjoy the benefits of the local waterways.

World Water Works, who hold exclusive licenses from DEMON GmbH for DEMON applications in the US and in India, specialize in developing, designing and manufacturing highly efficient process and wastewater solutions. These designs emphasize delivering clean water while recovering energy and other resource recovery.

CONTACT

Hugh Vaughan

Landia Ltd

Hugh Vaughan

www.landia.co.uk

+44 (0) 1948 661200

Thursday 19 February 2015 / file under Utilities | Environmental