Blower Powered Bottle Dryer Helps Ensure Product Integrity

Haus Rabenhorst is a leading producer of the highest quality natural fruit and vegetable juices in Germany, with a history that goes back over 200 years

Blower Powered Bottle Dryer PlantTheir product range, which comprises the finest quality un-diluted juices, covers more than 70 different fruit and vegetables.

At Rabenhorst close attention to detail applies to every aspect of production. This approach is reflected in the company’s farming practices to the way crops are grown; from the monitoring of produce quality to the strict minimisation of product processing and, finally, to the selection of the appropriate packing for the finished product.

This same attention to detail and the insistence of quality assurance was applied to the selection of the recently installed bottle drying system at the company’s premises in Unkel on the banks of the Rhine.

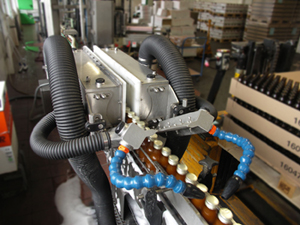

Supplied by Air Control Industries distributor in Germany, Carl von Gehlen of Mönchengladbach, it comprises a set of the company’s unique, blower-powered ‘JetPlates’ combined with a special cap drying unit. For Rabenhorst the bottle drying system will handle 125ml, 330ml and 500ml bottles.

There were a number of reasons why the ACI blower-powered bottle drying system was selected by Rabenhorst. In addition to the efficient drying it provides, there is the avoidance of compressed air and its inherent problems. These were identified by the company as high operating cost, potential safety hazards and the risk of product contamination.

The last point is particularly significant for Rabenhorst. With the company’s focus on purity and integrity of product, the potential hazards presented by contaminated compressed air were totally unacceptable.

The assembled ACI package supplied is based upon ACI’s EL (Eye Level) configuration employing the company’s JetPlate air delivery plenums. These have flat acrylic faces with stepped air slots that create a delivery pattern that drives moisture down and off the bottles. The smooth-face design of the plenums permits them to be positioned close to the bottles for maximum efficiency of air delivery whilst also acting as guide rails to prevent bottles falling over causing hold-ups in production.

Air is delivered by an ACI 15kW EP10A blower housed an acoustic enclosure with an air filter to ensure delivery of clean dry air.

Normally, the acoustic chamber is leg mounted so that it can be located either to one side of the bottling line or astride it. However at Rabenhorst the acoustic chamber is installed on top of a pasteurisation chamber, saving valuable floor space.

“Effective bottle drying is an essential requirement to ensure good product presentation and prevent the potential risk of rust contamination resulting from residual moisture trapped around the screw caps,” said Mr Egon Roos, Production Manager at Haus Rabenhorst. “The ACI bottle drying system works very well – we are very pleased with its performance and reliability.”

CONTACT

Mathew Forknall

Air Control Industries Ltd

mattforknall@aircontrolindustries.com

www.aircontrolindustries.com

+44 (0) 845 5000 501

Thursday 26 July 2012 / file under Food and Beverage | Packaging