Higher Efficiencies On Alternators

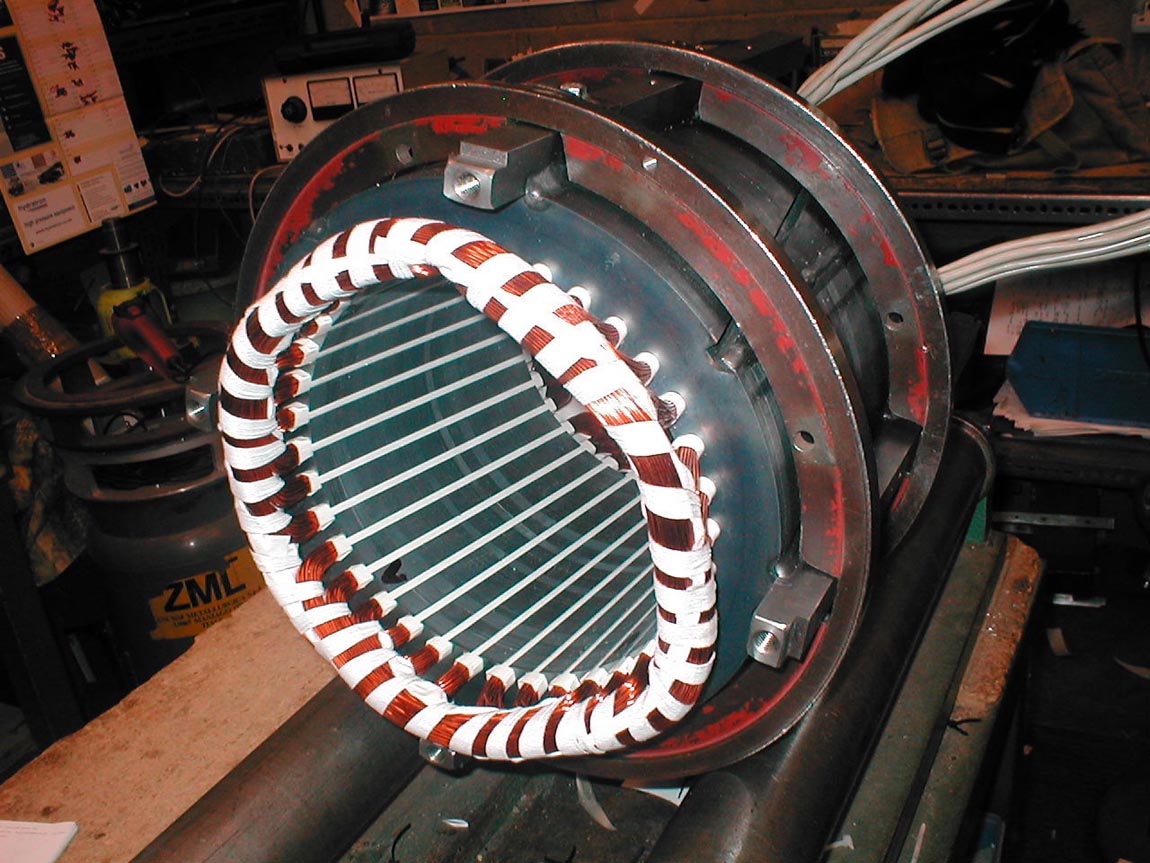

GENCOEEC Ltd a UK manufacturer of a compact range of Brushless alternators 2-100KVA and DC generators have announced that a complete re-design of the output windings to achieve higher efficiencies

The development was instigated by the continual rapid rise in world base copper prices; the new designs have been accomplished by an examination of the fundamental principles of producing rotating magnetic fluxes in rotating machines.

The new windings (using less copper winding wire), only use preformed coils for half the number of poles. Normally in a 4 pole machine the winding coils generate 2 south and 2north poles, whereas in the latest design the coils only produce 1 south and 1 north pole and by careful manipulation of the steel flux carrying laminations ‘’phantom poles’’ are produced to form the other 2 magnetic poles .This saves a significant amount of active copper with obvious cost saving and lower winding resistances resulting in lower copper losses and higher machine efficiencies .This of course reduces the prime movers fuel cost, usually diesel or gasoline .

Whilst developing the new windings coil insertion techniques were improved so that the winding overhang [inactive material] was minimized so reducing the electrical resistance and stray magnetic losses of the windings

Both of these improvements reduces the prime movers fuel cost, usually diesel or gasoline. Typical efficiency improvements of 3-5% are achieved with material cost saving of 15%.

CONTACT

Stan Ellsmore

Gencoeec Ltd

generators@gencoeec.co.uk

www.gencoeec.co.uk

+44 (0) 1780 721619

Monday 14 March 2011 / file under Agriculture | Machinery | Marine | New Products | Oil