ATOM Encoders Help JUSTEK Deliver Custom Motion Control Solutions That Drive Up Profits

Partnership with Renishaw makes a significant contribution to the success of JUSTEK Inc — a leading motion control component manufacturer based in Korea

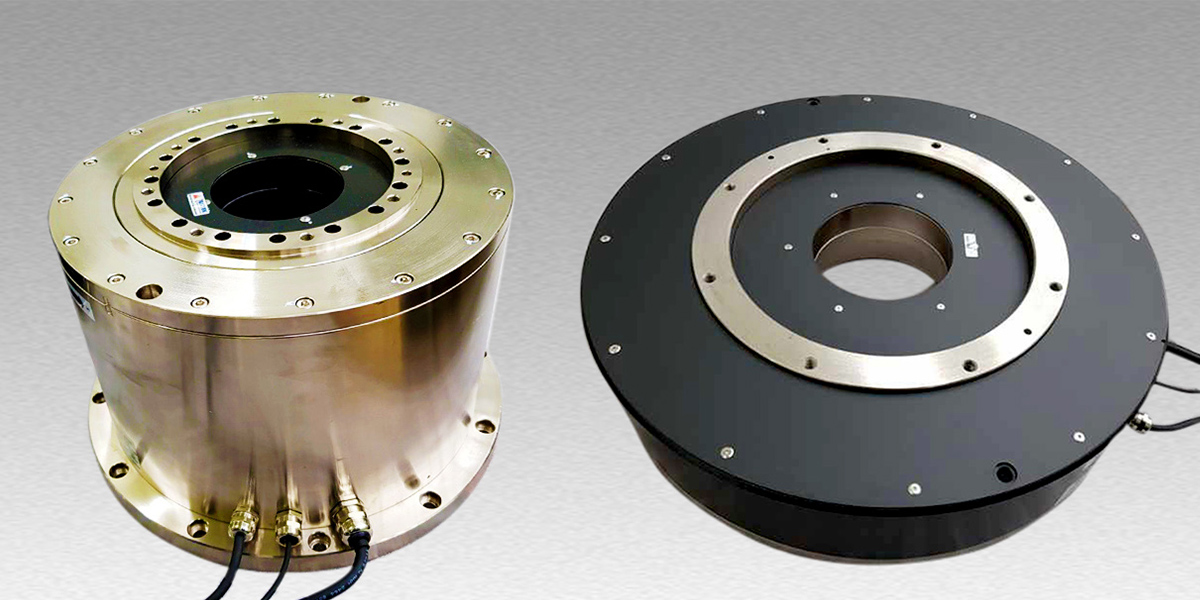

JUSTEK has developed a range of customisable direct-drive (DD) motors using Renishaw’s high-performance optical position encoders, including the miniature ATOM™ RCDM rotary encoder system, for the FPD and semiconductor/electronics industries.

Mr. Young-dong Jo, JUSTEK’s product manager, highlights the major benefits of the ATOM™ encoder:

“The miniature design of the ATOM™ readhead is ideal for our DD motors as space inside the motors is inherently limited. There are relatively few encoders options available on the market that meet our requirements for volume and performance. Before choosing ATOM™ optical encoders, we tested them repeatedly and found that the ATOM™ has advantages in terms of reliability, system volume and performance. Of course, Renishaw’s excellent after-sales service and technical support, and on-time delivery helped to strengthen the partnership between both companies.”

In addition to ATOM™, JUSTEK’s precision motion stages use other Renishaw optical encoder models, including the TONiC™ optical encoder series for OLED panel inspection equipment, and the RESOLUTE™ absolute encoder series for OLED panel inkjet printing equipment.

For quality control, JUSTEK tests and calibrates its motion control products prior to leaving the factory using Renishaw’s XL-80 laser system and XR20-W rotary axis calibrator. These systems are fast, extremely accurate with ±0.5 ppm linear measurement accuracy, lightweight and portable.

A value-added partnership with Renishaw has enabled JUSTEK to build bespoke motion control systems for its customers that drive increased orders and higher profits.

As Mr Young-dong Jo explains: “Product flexibility is one of our strengths. In today’s highly competitive market, the ability to quickly respond to customers’ needs is key to our success. Sometimes, we need to provide customers with customized DD motors, rotary tables and linear stages. Renishaw impressed us in this regard. For a DD motor project, Renishaw supplied a custom encoder scale that provides a non-standard resolution which allows our end-users to seamlessly connect to their original controllers — providing us with a perfect solution to win orders.”

Renishaw’s ATOM™ optical encoder is one of only a handful of integrated miniaturised optical encoders available on the market and features a wide range of scale options, leading-edge signal stability, dirt immunity and reliability.

CONTACT

Chris Pockett

Renishaw plc

uk@renishaw.com

www.renishaw.com

+44 1453 524524

Thursday 29 October 2020 / file under Electronics | Engineering | Technology