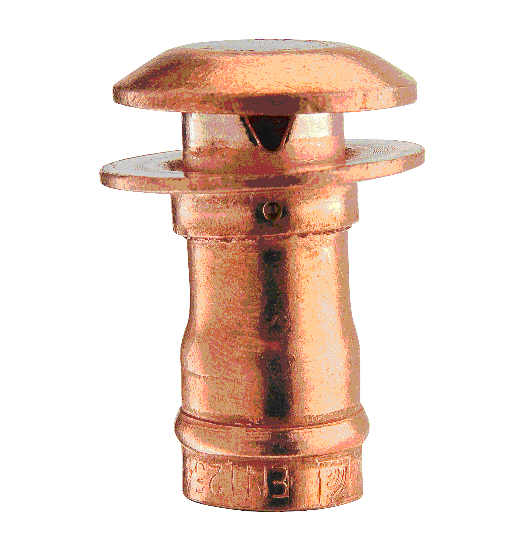

The Pipe Cowl From Flowflex For Pressure Relief Termination

The Pipe Cowl offers an alternative solution for pressure relief termination

You often find that installers tend to use a couple of 90-degree elbows for the pressure relief termination however this could be seen as time consuming and unsightly.

The Pipe Cowl offers the quickest, neatest and lowest cost installation solution for pressure relief termination. Installing a pipe cowl requires just a single soldered joint enabling quick and easy installation.

“Quicker than bending a pipe to face the wall or using 2 x 90 elbows. Less exposed for vandals or copper thieves” – Plumbing / Heating Engineer

Originally available in 15mm & 22mm an Extended version is now available.

Although having the same end as a standard size pipe cowl, the extended version has an additional 500mm of copper pipe which enables installation to be completed from inside the building.

The Extended Pipe Cowl can be installed, inside, by pushing the fitting through a pre-drilled hole and when pulling the fitting back a rubber washer creates a seal against the wall. This means installation in high rise buildings can take place without the need of scaffolding or abseiling saving both time and money.

The Pipe Cowl in manufactured to EN1254 and complies with all current legislation. The Pipe Cowl is the quickest, neatest and lowest cost installation solution for pressure relief termination.

“A very simple piece of kit, sends the hot water in all directions over wall not at anyone in the event of a pressure relief. Small size equals less danger of being vandalised or stolen like a length of copper pipe could be and a Yorkshire fitting as well.” – DIY’er

CONTACT

Paul Niklas

Flowflex Components Ltd

sales@flowflex.com

www.flowflex.com

+44 1298 77211

Friday 29 June 2018 / file under Construction | Engineering | Household | Water